Growing Focus on Sustainability

The Automotive Parts Zinc Die Casting Market is increasingly influenced by a growing focus on sustainability. As consumers and manufacturers alike prioritize environmentally friendly practices, the demand for recyclable materials is on the rise. Zinc die casting is recognized for its recyclability and lower environmental impact compared to other materials. This shift towards sustainable manufacturing processes is prompting automotive companies to incorporate zinc die-cast components into their designs. In 2025, it is estimated that sustainable automotive practices will contribute to a market growth of approximately 15 billion USD. This trend indicates that the Automotive Parts Zinc Die Casting Market is likely to align with broader sustainability goals, enhancing its appeal to eco-conscious consumers.

Rising Demand for Lightweight Materials

The Automotive Parts Zinc Die Casting Market is experiencing a notable increase in demand for lightweight materials. This trend is primarily driven by the automotive sector's focus on enhancing fuel efficiency and reducing emissions. Zinc die casting offers a favorable strength-to-weight ratio, making it an attractive option for manufacturers. As automakers strive to meet stringent regulatory standards, the adoption of zinc die-cast components is likely to rise. In 2025, the market for lightweight automotive components is projected to reach approximately 100 billion USD, indicating a robust growth trajectory. This shift towards lightweight materials not only aids in compliance with environmental regulations but also enhances vehicle performance, thereby propelling the Automotive Parts Zinc Die Casting Market forward.

Increased Production of Electric Vehicles

The Automotive Parts Zinc Die Casting Market is poised for growth due to the escalating production of electric vehicles (EVs). As the automotive landscape shifts towards electrification, manufacturers are increasingly utilizing zinc die casting for various components, including battery housings and structural parts. The lightweight nature of zinc die-cast components contributes to improved energy efficiency in EVs, which is a critical factor for consumers. In 2025, the EV market is expected to account for over 30% of total vehicle sales, further driving the demand for zinc die-cast parts. This trend suggests that the Automotive Parts Zinc Die Casting Market will likely see a significant uptick in orders as automakers adapt to the evolving market dynamics.

Technological Innovations in Die Casting Processes

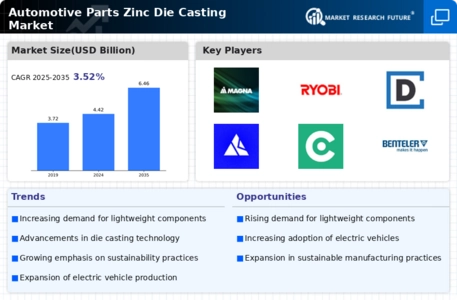

Technological advancements in die casting processes are significantly influencing the Automotive Parts Zinc Die Casting Market. Innovations such as improved mold designs, automated production lines, and enhanced alloy formulations are streamlining manufacturing processes and increasing efficiency. These advancements not only reduce production costs but also improve the quality and precision of die-cast components. As a result, manufacturers are more inclined to adopt zinc die casting for complex automotive parts. The market is expected to witness a compound annual growth rate (CAGR) of around 5% through 2025, driven by these technological improvements. Consequently, the Automotive Parts Zinc Die Casting Market is likely to benefit from enhanced production capabilities and reduced lead times.

Expansion of Automotive Manufacturing in Emerging Markets

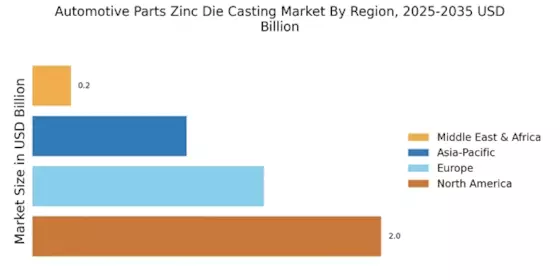

The Automotive Parts Zinc Die Casting Market is benefiting from the expansion of automotive manufacturing in emerging markets. Countries in Asia and South America are witnessing a surge in automotive production, driven by rising disposable incomes and increasing urbanization. This growth is leading to a higher demand for automotive components, including those made from zinc die casting. In 2025, it is projected that automotive production in these regions will increase by over 20%, creating substantial opportunities for zinc die-cast manufacturers. As automakers seek to optimize production costs and improve supply chain efficiencies, the Automotive Parts Zinc Die Casting Market is likely to experience robust growth in these emerging markets.