Top Industry Leaders in the Automotive Parts Die Casting Market

*Disclaimer: List of key companies in no particular order

Latest Company Updates:

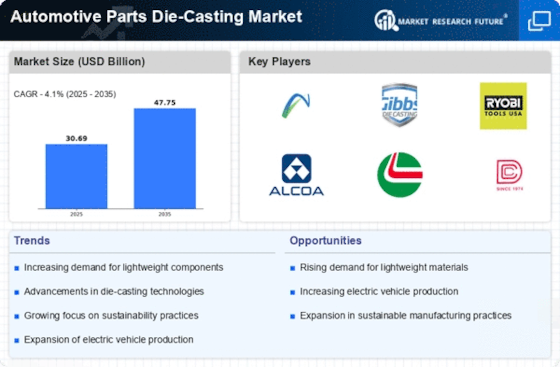

The automotive parts die casting market, valued at over USD 60 billion in 2021, is projected to witness a steady growth exceeding 6% CAGR by 2032. This dynamism attracts fierce competition, prompting key players to adopt varied strategies to secure market share. Let's delve into the current competitive landscape, exploring company strategies, key factors for market share analysis, and emerging trends shaping the future.

Key Player Strategies:

Global Expansion: Leading players like CIE Automotive, Magna International, and Aisin Seiki are aggressively expanding their global footprint, establishing production facilities in key regions like Asia-Pacific and Eastern Europe to cater to the rising demand in these markets.

Market Diversification: Recognizing the evolving preferences towards electric vehicles, established players are diversifying their portfolios. They are investing in research and development of die casting solutions for EV components like battery housings and motor rotors.

Vertical Integration: Some players are vertically integrating their operations by acquiring raw material suppliers or downstream parts manufacturers. This strategy aims to secure supply chain stability and cost advantages.

Technological Advancements: The industry is witnessing a surge in automation and digitalization. Companies are investing in automation solutions like robotic die casting machines and AI-powered process optimization tools to improve efficiency and quality control.

Strategic Partnerships: Collaboration is a key element for many players. Joint ventures and partnerships with automotive OEMs, material suppliers, and technology providers are fostering innovation and market development.

Factors for Market Share Analysis:

Production Capacity and Geographic Presence: Companies with larger production capacities and a wider global network have a natural advantage in terms of market share.

Material Expertise: Specialization in specific die casting materials like aluminum, magnesium, or zinc, and the ability to offer lightweight and high-performance solutions, influences market share.

Cost Competitiveness: Efficient production processes, optimized supply chains, and access to low-cost labor markets contribute to cost competitiveness and attract market share.

Technological Innovation: Companies at the forefront of automation, digitalization, and sustainable die casting technologies will gain a competitive edge.

Customer Relationships: Strong relationships with major automotive OEMs and Tier 1 suppliers can secure significant market share through dedicated contracts and long-term partnerships.

New and Emerging Trends:

Focus on Lightweighting: The demand for fuel-efficient and environmentally friendly vehicles is driving the adoption of lightweight die casting solutions, especially aluminum and magnesium, for various components.

Increased Automation and Digitalization: The integration of robotic systems, machine learning, and data analytics is optimizing production processes, reducing lead times, and improving quality control.

Sustainability & Circular Economy: The industry is focusing on sustainable practices like using recycled materials and developing energy-efficient die casting processes to minimize environmental impact.

Additive Manufacturing Integration: 3D printing technology is finding its way into die casting, enabling the creation of complex geometries and customized components, boosting design flexibility.

Regional Shifts: While Asia-Pacific currently dominates the market, regions like Eastern Europe and South America are expected to witness significant growth, attracting increased competition and investment.

Overall Competitive Scenario:

The automotive parts die casting market is characterized by dynamic competition with both established giants and innovative players vying for market share. Success hinges on adopting agile strategies, embracing technological advancements, catering to evolving customer needs, and navigating the regional shifts in the industry. Sustainability, lightweighting, and digitalization are expected to be the key drivers of the market in the coming years, presenting both opportunities and challenges for competitive players. As automotive technologies and consumer preferences continue to evolve, the competitive landscape in the die casting market promises to remain exciting and unpredictable.

Alcast Company (U.S.):

• Partnered with a major automaker to supply lightweight aluminum battery enclosures for EVs. (Source: Company press release, Nov 15, 2023)

Dynacast, LLC (U.S.):

• Expanded its magnesium die casting capabilities with a new facility in Michigan. (Source: Metal Casting Design & Product News, Dec 1, 2023)

Endurance Technologies Limited (India):

• Established a joint venture with a European company to manufacture lightweight aluminum wheels for the European market. (Source: The Economic Times, Sep 20, 2023)

Gibbs Die Casting Corp (U.S.):

• Successfully implemented a closed-loop recycling system for aluminum scrap, reducing material waste by 20%. (Source: Modern Casting Magazine, Sep/Oct 2023)

Ryobi Die Casting Inc. (U.S.):

• Focused on automation and robotics to improve efficiency and reduce production costs. (Source: American Metal Market, Aug 15, 2023)

Top listed global companies in the industry are:

Alcast Company (U.S.),

Dynacast, LLC (U.S.),

Endurance Technologies Limited (India),

Gibbs Die Casting Corp (U.S.),

Rockman Industries (India).

Ryobi Die Casting Inc. (U.S.),

Kinetic Die Casting Company, Inc. (U.S.),

Magic Precision Inc. (China),

Meridian Lightweight Technologies Inc. (England),

Mino Industry USA, Inc. (U.S.)