Growing Electric Vehicle Production

The rise in electric vehicle production is a notable driver for the Automotive Paint Robot Market. As automakers pivot towards electric vehicles, the demand for efficient and high-quality painting solutions is escalating. Electric vehicles often require specialized coatings to enhance their performance and aesthetics, which can be effectively achieved through robotic painting systems. The market for electric vehicles is projected to grow at a compound annual growth rate of 22% through 2030, indicating a substantial opportunity for the automotive paint robot sector. This trend suggests that the Automotive Paint Robot Market will benefit from the increasing production of electric vehicles, as manufacturers seek advanced painting technologies to meet the unique requirements of this evolving market.

Cost Efficiency and Productivity Gains

Cost efficiency is a critical driver in the Automotive Paint Robot Market. The adoption of robotic painting systems allows manufacturers to significantly reduce labor costs and improve overall productivity. By automating the painting process, companies can achieve faster production cycles and lower operational expenses. Studies indicate that manufacturers utilizing paint robots can increase their output by up to 30%, while also reducing paint consumption through precise application techniques. This efficiency not only enhances profitability but also enables manufacturers to remain competitive in a rapidly changing market. As a result, the Automotive Paint Robot Market is likely to see continued investment in robotic technologies as companies seek to optimize their operations and drive down costs.

Technological Advancements in Robotics

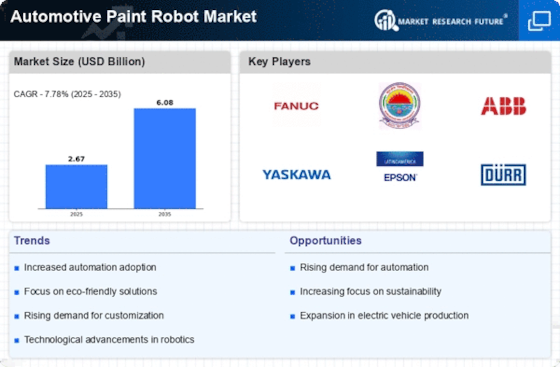

Technological advancements play a pivotal role in the Automotive Paint Robot Market. Innovations in robotics, such as artificial intelligence and machine learning, are enhancing the capabilities of paint robots. These technologies enable robots to adapt to various painting conditions and optimize their performance in real-time. For instance, the introduction of vision systems allows robots to detect surface imperfections and adjust their painting techniques accordingly. As a result, manufacturers can achieve superior finishes while reducing material waste. The market for automotive paint robots is projected to grow at a compound annual growth rate of 7.5% from 2023 to 2028, driven by these technological improvements. This trend indicates that the Automotive Paint Robot Market is on the cusp of a technological revolution, which could redefine manufacturing processes.

Increased Demand for High-Quality Finishes

The Automotive Paint Robot Market is experiencing a surge in demand for high-quality finishes in vehicle manufacturing. As consumers increasingly prioritize aesthetics and durability, manufacturers are compelled to adopt advanced painting technologies. This shift is evident in the projected growth of the automotive paint robot market, which is expected to reach USD 1.5 billion by 2026. The precision and consistency offered by robotic systems ensure that vehicles meet stringent quality standards, thereby enhancing customer satisfaction. Furthermore, the integration of robotics in painting processes minimizes human error, leading to fewer defects and rework. Consequently, the Automotive Paint Robot Market is likely to expand as manufacturers seek to improve their production capabilities and meet evolving consumer expectations.

Regulatory Compliance and Safety Standards

The Automotive Paint Robot Market is significantly influenced by regulatory compliance and safety standards. Governments worldwide are implementing stringent regulations regarding emissions and worker safety in manufacturing environments. As a response, automotive manufacturers are increasingly adopting robotic painting solutions to comply with these regulations. Robotic systems not only reduce volatile organic compound emissions but also enhance workplace safety by minimizing human exposure to hazardous materials. The market is expected to witness a steady increase in demand for paint robots as manufacturers strive to meet these compliance requirements. This trend suggests that the Automotive Paint Robot Market will continue to evolve, driven by the need for sustainable and safe manufacturing practices.