Global Supply Chain Optimization

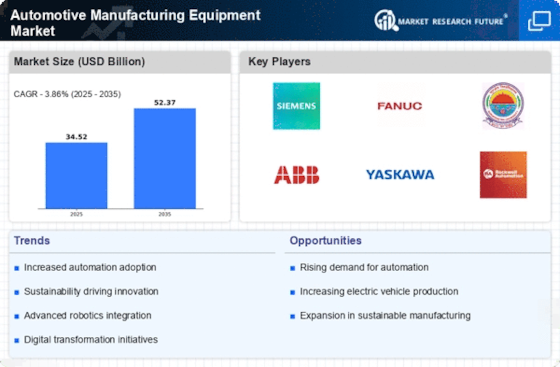

The Automotive Manufacturing Equipment Market is significantly influenced by the need for supply chain optimization. As manufacturers strive to enhance efficiency and reduce costs, they are increasingly adopting advanced manufacturing technologies that streamline operations. The implementation of just-in-time production methods and lean manufacturing principles has become prevalent, allowing companies to minimize waste and improve inventory management. According to recent data, companies that have optimized their supply chains have reported a reduction in production costs by approximately 15%. This trend is likely to continue, as manufacturers seek to enhance their competitive edge through improved supply chain strategies, thereby driving demand for innovative manufacturing equipment.

Increased Focus on Sustainability

Sustainability has emerged as a critical driver in the Automotive Manufacturing Equipment Market. Manufacturers are increasingly adopting eco-friendly practices and technologies to reduce their carbon footprint. This includes the use of energy-efficient machinery and the implementation of recycling processes within manufacturing operations. Recent studies indicate that companies prioritizing sustainability are likely to see a 20% increase in consumer preference. As a result, there is a growing demand for equipment that not only meets production needs but also aligns with environmental standards. This focus on sustainability is expected to shape the future of the automotive manufacturing equipment market, as manufacturers seek to balance profitability with ecological responsibility.

Rising Demand for Electric Vehicles

The shift towards electric vehicles (EVs) is reshaping the Automotive Manufacturing Equipment Market. As manufacturers pivot to meet the growing consumer demand for EVs, there is an increasing need for specialized equipment designed for electric powertrains and battery production. This transition is not merely a trend; it is projected that by 2030, electric vehicles could represent over 30% of total vehicle sales. Consequently, manufacturers are investing heavily in new equipment and technologies tailored for EV production. This shift not only influences the types of machinery required but also drives innovation in manufacturing processes, thereby creating new opportunities within the automotive manufacturing equipment sector.

Customization and Consumer Preferences

The Automotive Manufacturing Equipment Market is also driven by the increasing demand for customization in vehicle production. As consumer preferences evolve, manufacturers are compelled to adopt flexible manufacturing systems that allow for the production of tailored vehicles. This trend is evident in the rise of modular production techniques, which enable manufacturers to efficiently produce a variety of models on the same assembly line. Data suggests that companies offering customizable options can achieve a 25% increase in customer satisfaction. Consequently, the need for versatile manufacturing equipment that can accommodate these changes is becoming paramount, thereby influencing the overall dynamics of the automotive manufacturing equipment market.

Technological Advancements in Manufacturing Equipment

The Automotive Manufacturing Equipment Market is experiencing a surge in technological advancements, particularly in automation and artificial intelligence. These innovations enhance production efficiency and reduce operational costs. For instance, the integration of advanced robotics in assembly lines has been shown to increase productivity by up to 30%. Furthermore, the adoption of Industry 4.0 principles allows manufacturers to leverage data analytics for predictive maintenance, thereby minimizing downtime. As a result, companies are increasingly investing in state-of-the-art equipment to remain competitive. The market for automotive manufacturing equipment is projected to grow significantly, driven by these technological enhancements, which are expected to account for a substantial share of the overall market growth in the coming years.