Rising Fuel Prices

The Global Automotive Lightweighting Market Industry is also shaped by the rising costs of fuel, which compel consumers and manufacturers alike to seek more fuel-efficient vehicles. Lightweighting contributes to improved fuel economy, making vehicles more attractive in a market where fuel prices are volatile. For example, a reduction of 10% in vehicle weight can lead to a fuel economy improvement of approximately 6-8%. This correlation between weight and fuel efficiency is driving automakers to invest in lightweight materials. Consequently, the market is anticipated to grow, with projections indicating a value of 166.7 USD Billion by 2035, as manufacturers prioritize fuel efficiency in their designs.

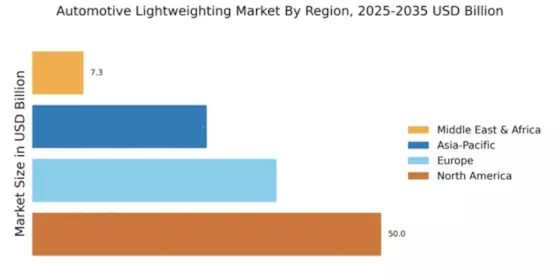

Market Growth Projections

The Global Automotive Lightweighting Market Industry is projected to experience substantial growth over the coming years. With a market value anticipated to reach 112.6 USD Billion in 2024 and further expanding to 166.7 USD Billion by 2035, the industry is poised for a robust trajectory. The expected compound annual growth rate (CAGR) of 3.63% from 2025 to 2035 underscores the increasing adoption of lightweight materials across various vehicle segments. This growth is driven by a combination of regulatory pressures, consumer preferences, and technological advancements, indicating a dynamic and evolving landscape for automotive lightweighting.

Increased Focus on Sustainability

The Global Automotive Lightweighting Market Industry is increasingly aligned with the global push for sustainability. As environmental concerns gain prominence, automakers are prioritizing lightweighting as a strategy to reduce their ecological impact. Lightweight vehicles consume less energy, thereby lowering greenhouse gas emissions throughout their lifecycle. This focus on sustainability is driving investments in research and development of eco-friendly materials and manufacturing processes. The market's growth is indicative of this trend, as stakeholders recognize the importance of aligning with sustainability goals, ensuring that lightweighting remains a critical component of future automotive design.

Technological Advancements in Materials

The Global Automotive Lightweighting Market Industry is significantly influenced by ongoing technological advancements in materials science. Innovations in composite materials and high-strength steel are enabling manufacturers to achieve weight reductions without compromising safety or performance. For instance, the development of carbon fiber reinforced plastics has opened new avenues for lightweighting in high-performance vehicles. These advancements not only enhance vehicle dynamics but also contribute to overall sustainability goals. As manufacturers increasingly adopt these cutting-edge materials, the market is poised for growth, reflecting a shift towards more innovative and efficient automotive solutions.

Regulatory Pressure for Emission Reduction

The Global Automotive Lightweighting Market Industry is increasingly influenced by stringent regulations aimed at reducing vehicle emissions. Governments worldwide are implementing policies that mandate lower carbon footprints for vehicles, driving manufacturers to adopt lightweight materials. For instance, the European Union has set ambitious targets for CO2 emissions, compelling automakers to innovate in material usage. This regulatory environment is expected to propel the market, as lightweighting can lead to significant reductions in fuel consumption and emissions. As a result, the Global Automotive Lightweighting Market is projected to reach 112.6 USD Billion in 2024, reflecting the industry's response to these regulatory challenges.

Consumer Demand for Performance and Efficiency

The Global Automotive Lightweighting Market Industry is experiencing heightened consumer demand for vehicles that offer enhanced performance and efficiency. As consumers become more discerning, they seek vehicles that not only perform well but also provide better fuel economy. Lightweight materials, such as aluminum and advanced composites, enable manufacturers to produce vehicles that are both lighter and more powerful. This trend is evident in the growing popularity of electric vehicles, which benefit significantly from weight reduction. The emphasis on performance and efficiency is likely to sustain the market's growth trajectory, with a projected CAGR of 3.63% from 2025 to 2035, indicating a robust future for lightweighting technologies.