Cost Efficiency

Cost efficiency remains a critical driver for the Automotive Hydroformed Parts Market. The hydroforming process, which utilizes fewer materials and reduces waste, can lead to significant cost savings for manufacturers. By minimizing the amount of raw material required, companies can lower production costs while maintaining high-quality standards. Additionally, the ability to produce complex shapes in a single operation reduces the need for multiple manufacturing steps, further enhancing cost-effectiveness. Market data indicates that manufacturers adopting hydroforming techniques can achieve up to a 20% reduction in production costs compared to traditional methods. This financial advantage is particularly appealing in a competitive automotive landscape, where cost pressures are prevalent. As a result, the Automotive Hydroformed Parts Market is poised for growth as manufacturers seek to optimize their operations and improve profitability.

Regulatory Compliance

Regulatory compliance is increasingly shaping the Automotive Hydroformed Parts Market. As governments worldwide implement stricter emissions and safety regulations, manufacturers are compelled to adopt advanced production techniques that meet these standards. Hydroforming, with its ability to produce lightweight and structurally sound components, aligns well with regulatory requirements aimed at reducing vehicle emissions and enhancing safety. The market is witnessing a trend where compliance with these regulations drives innovation and investment in hydroforming technologies. Furthermore, the Automotive Hydroformed Parts Market is likely to benefit from incentives provided by governments to promote the use of advanced manufacturing processes. This regulatory landscape suggests a favorable environment for the growth of hydroformed parts, as manufacturers strive to meet compliance while enhancing their product offerings.

Electric Vehicle Demand

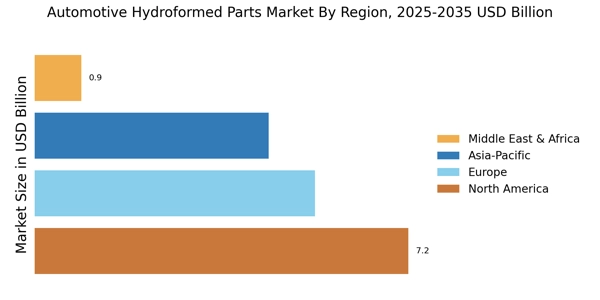

The rising demand for electric vehicles (EVs) is significantly impacting the Automotive Hydroformed Parts Market. As automakers pivot towards electrification, the need for lightweight and efficient components becomes paramount. Hydroformed parts, known for their strength-to-weight ratio, are ideal for EV applications, where reducing weight can enhance battery performance and range. Market analysis suggests that the EV segment is expected to account for a substantial share of the automotive market, with projections indicating that EV sales could reach 30% of total vehicle sales by 2030. This shift presents a lucrative opportunity for hydroformed parts manufacturers to cater to the evolving needs of the automotive industry. Consequently, the Automotive Hydroformed Parts Market is likely to experience growth as it aligns with the trends of electrification and sustainability.

Technological Innovations

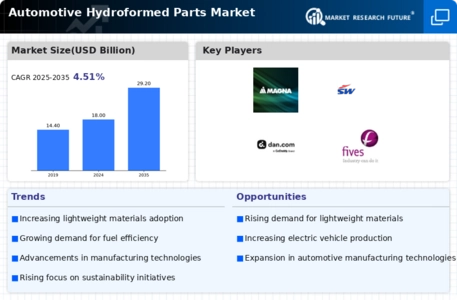

Technological innovations play a pivotal role in shaping the Automotive Hydroformed Parts Market. Advancements in hydroforming techniques, such as the development of high-pressure hydroforming, have significantly improved the precision and quality of parts produced. These innovations enable manufacturers to create complex geometries that were previously unattainable, thus expanding the application range of hydroformed components. The integration of automation and robotics in the manufacturing process further enhances efficiency and reduces production costs. As the automotive industry increasingly embraces Industry 4.0 principles, the demand for technologically advanced hydroformed parts is expected to rise. Market data indicates that the adoption of these technologies could lead to a compound annual growth rate of over 5% in the coming years. This trend underscores the importance of continuous innovation within the Automotive Hydroformed Parts Market.

Sustainability Initiatives

The Automotive Hydroformed Parts Market is increasingly influenced by sustainability initiatives. As manufacturers strive to reduce their carbon footprint, hydroforming emerges as a preferred method due to its efficiency and reduced material waste. This process allows for the creation of lightweight components, which can enhance fuel efficiency in vehicles. In recent years, the automotive sector has seen a shift towards eco-friendly practices, with hydroformed parts being integral to this transition. The market is projected to grow as more companies adopt sustainable manufacturing processes, aligning with consumer demand for greener vehicles. Furthermore, regulatory pressures are likely to drive investments in hydroforming technologies, as automakers seek to comply with stringent environmental standards. This trend suggests a robust future for the Automotive Hydroformed Parts Market, as sustainability becomes a core focus for manufacturers.