Growing Aftermarket Segment

The Automotive Helical Coil Spring Market is benefiting from the expansion of the aftermarket segment, as vehicle owners increasingly seek to enhance their vehicles' performance and aesthetics. The aftermarket for automotive parts, including helical coil springs, is projected to grow significantly, with estimates suggesting a market size of over 300 billion by 2026. This growth is fueled by a rising trend in vehicle customization, where consumers opt for upgraded suspension systems to improve handling and ride quality. As a result, manufacturers are focusing on producing a diverse range of helical coil springs tailored for aftermarket applications, thereby creating new opportunities within the Automotive Helical Coil Spring Market.

Increased Vehicle Production

The Automotive Helical Coil Spring Market is poised for growth due to the rising production of vehicles across various segments. As automotive manufacturers ramp up production to meet consumer demand, the need for reliable suspension components, including helical coil springs, becomes paramount. Recent data indicates that global vehicle production is expected to reach over 100 million units annually by 2026, creating a substantial market for helical coil springs. This increase in production is likely to drive innovation in spring design and materials, as manufacturers seek to enhance performance and durability. Consequently, the Automotive Helical Coil Spring Market stands to benefit significantly from this upward trend in vehicle manufacturing.

Rising Demand for Lightweight Vehicles

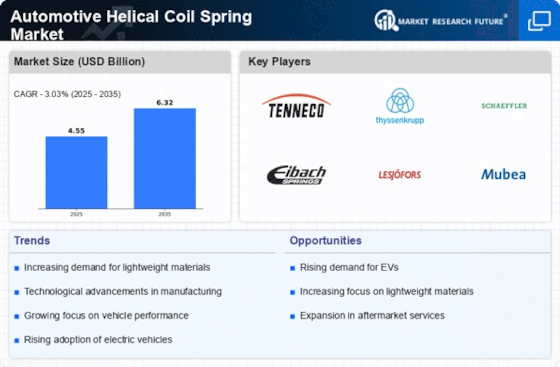

The Automotive Helical Coil Spring Market is experiencing a notable shift towards lightweight vehicles, driven by consumer preferences for fuel efficiency and reduced emissions. Manufacturers are increasingly adopting lightweight materials and designs to enhance vehicle performance. This trend is reflected in the growing production of electric and hybrid vehicles, which often utilize advanced helical coil springs to optimize weight distribution and handling. As a result, the demand for high-quality, lightweight helical coil springs is projected to rise, with estimates suggesting a compound annual growth rate of approximately 5% over the next five years. This shift not only aligns with environmental goals but also caters to the evolving expectations of consumers seeking more efficient and agile vehicles.

Regulatory Compliance and Safety Standards

The Automotive Helical Coil Spring Market is influenced by stringent regulatory compliance and safety standards imposed on vehicle manufacturers. Governments worldwide are increasingly mandating higher safety and performance benchmarks for vehicles, which directly impacts the design and quality of suspension components, including helical coil springs. Compliance with these regulations often necessitates the use of advanced materials and manufacturing processes, thereby driving innovation within the industry. As manufacturers strive to meet these evolving standards, the demand for high-performance helical coil springs is likely to increase. This trend not only enhances vehicle safety but also propels the Automotive Helical Coil Spring Market towards greater technological advancements and improved product offerings.

Technological Innovations in Suspension Systems

The Automotive Helical Coil Spring Market is witnessing a surge in technological innovations that enhance the performance of suspension systems. Advancements in materials science and engineering have led to the development of helical coil springs that offer improved strength-to-weight ratios and fatigue resistance. These innovations are crucial for modern vehicles, which require suspension components that can withstand varying loads and driving conditions. Furthermore, the integration of smart technologies in suspension systems, such as adaptive damping and electronic control, is likely to increase the demand for specialized helical coil springs. As a result, the Automotive Helical Coil Spring Market is expected to evolve rapidly, driven by these technological advancements.