Rising Production of Electric Vehicles

The surge in electric vehicle (EV) production is reshaping the Automotive Die Casting Lubricant Market. As automakers pivot towards electric mobility, the demand for lightweight and efficient components becomes paramount. Die casting plays a crucial role in producing parts for EVs, necessitating the use of specialized lubricants that can enhance the casting process. Reports indicate that the EV market is anticipated to grow at a staggering rate, with projections suggesting that electric vehicles could account for over 30% of total vehicle sales by 2030. This shift is likely to drive the demand for high-performance die casting lubricants tailored for the unique requirements of electric vehicle manufacturing.

Technological Innovations in Lubricants

Technological advancements in lubricant formulations are significantly influencing the Automotive Die Casting Lubricant Market. Innovations such as the development of bio-based lubricants and advanced synthetic formulations are enhancing the performance and sustainability of die casting lubricants. These innovations not only improve the efficiency of the die casting process but also address environmental concerns associated with traditional lubricants. The market for advanced lubricants is expected to expand, with a projected growth rate of approximately 6% annually, as manufacturers increasingly adopt these new technologies to meet regulatory standards and consumer preferences for greener products.

Focus on Cost Efficiency in Manufacturing

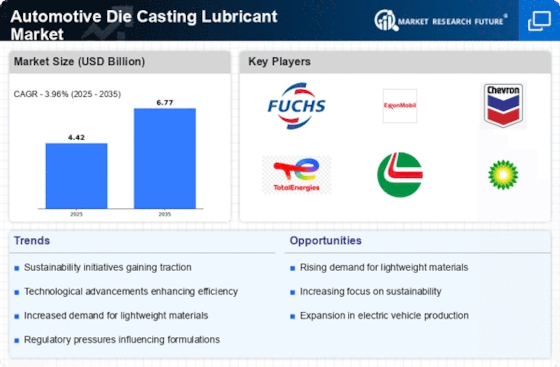

Cost efficiency remains a critical driver in the Automotive Die Casting Lubricant Market. Manufacturers are increasingly seeking ways to reduce production costs while maintaining high-quality standards. The use of effective die casting lubricants can lead to significant savings by minimizing wear and tear on machinery, reducing scrap rates, and enhancing overall production efficiency. As companies strive to optimize their operations, the demand for lubricants that offer both performance and cost-effectiveness is likely to increase. Market analyses suggest that the focus on cost efficiency could lead to a growth rate of around 4% in the lubricant segment, as manufacturers prioritize solutions that deliver tangible economic benefits.

Increasing Demand for Lightweight Vehicles

The automotive industry is witnessing a pronounced shift towards lightweight vehicles, driven by the need for improved fuel efficiency and reduced emissions. This trend is particularly relevant in the Automotive Die Casting Lubricant Market, where die casting processes are employed to produce lightweight components. As manufacturers seek to optimize their production methods, the demand for specialized lubricants that enhance the die casting process is likely to rise. According to industry reports, the lightweight vehicle segment is projected to grow at a compound annual growth rate of over 5% in the coming years, further propelling the need for effective lubricants that can withstand high temperatures and pressures during casting.

Regulatory Compliance and Environmental Standards

The Automotive Die Casting Lubricant Market is increasingly influenced by stringent regulatory compliance and environmental standards. Governments worldwide are implementing regulations aimed at reducing the environmental impact of manufacturing processes, including the use of lubricants. This has prompted manufacturers to seek lubricants that not only comply with these regulations but also enhance the sustainability of their operations. The market for eco-friendly lubricants is expected to grow, with estimates indicating a potential increase of 5% annually as companies adapt to these evolving standards. The emphasis on regulatory compliance is likely to drive innovation in lubricant formulations, fostering the development of more sustainable options.