Market Growth Projections

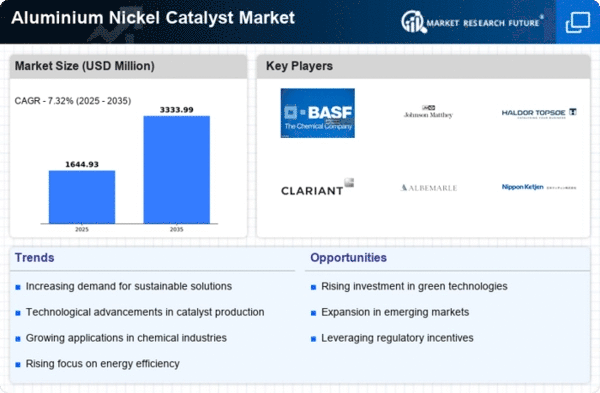

The Global Aluminium Nickel Catalyst Market Industry is projected to experience substantial growth in the coming years. With a market valuation of 1.53 USD Billion in 2024, it is anticipated to reach 3.34 USD Billion by 2035. This growth trajectory indicates a compound annual growth rate (CAGR) of 7.35% from 2025 to 2035. The increasing demand for efficient and sustainable catalysts across various industries is likely to drive this expansion. As companies continue to innovate and adopt advanced catalytic solutions, the aluminium nickel catalyst market is poised for significant development.

Expansion of Chemical Manufacturing

The Global Aluminium Nickel Catalyst Market Industry is significantly influenced by the expansion of chemical manufacturing sectors worldwide. As countries invest in infrastructure and industrial capabilities, the demand for catalysts that enhance production efficiency is rising. Aluminium nickel catalysts play a crucial role in various chemical reactions, thereby improving yield and reducing waste. This growth is projected to contribute to a market valuation of 3.34 USD Billion by 2035, indicating a robust expansion trajectory. The increasing complexity of chemical processes necessitates advanced catalysts, further driving the adoption of aluminium nickel catalysts across diverse applications.

Technological Advancements in Catalysis

Technological advancements in catalysis are reshaping the Global Aluminium Nickel Catalyst Market Industry. Innovations in catalyst design and synthesis techniques are enhancing the performance and selectivity of aluminium nickel catalysts. These advancements enable industries to achieve higher efficiency and lower operational costs. As a result, the market is expected to witness a compound annual growth rate (CAGR) of 7.35% from 2025 to 2035. This growth is indicative of the increasing reliance on advanced catalytic solutions to meet the evolving demands of various sectors, including automotive and energy.

Growing Demand for Sustainable Catalysts

The Global Aluminium Nickel Catalyst Market Industry experiences a notable increase in demand for sustainable catalysts. Industries are increasingly focusing on reducing their carbon footprint and enhancing energy efficiency. Aluminium nickel catalysts are recognized for their potential to facilitate greener chemical processes, which aligns with global sustainability goals. As a result, the market is projected to reach 1.53 USD Billion in 2024, reflecting a shift towards environmentally friendly alternatives. This trend is particularly evident in sectors such as petrochemicals and pharmaceuticals, where the adoption of sustainable practices is becoming a priority.

Regulatory Support for Clean Technologies

Regulatory support for clean technologies is a driving force in the Global Aluminium Nickel Catalyst Market Industry. Governments worldwide are implementing policies and incentives to promote the use of cleaner production methods. This regulatory framework encourages industries to adopt aluminium nickel catalysts, which are known for their efficiency in facilitating environmentally friendly reactions. The alignment of regulatory measures with sustainability goals is likely to accelerate market growth, as companies seek to comply with stringent environmental standards. This trend underscores the importance of aluminium nickel catalysts in achieving compliance and enhancing overall operational sustainability.

Increasing Applications in Renewable Energy

The Global Aluminium Nickel Catalyst Market Industry is witnessing an increase in applications within the renewable energy sector. As the world shifts towards sustainable energy sources, aluminium nickel catalysts are being utilized in processes such as hydrogen production and biofuel synthesis. These catalysts enhance the efficiency of reactions, making them essential for the development of clean energy technologies. The growing emphasis on renewable energy is expected to bolster the market, as industries seek effective solutions to optimize production processes. This trend highlights the pivotal role of aluminium nickel catalysts in supporting the transition to a more sustainable energy landscape.