Technological Advancements

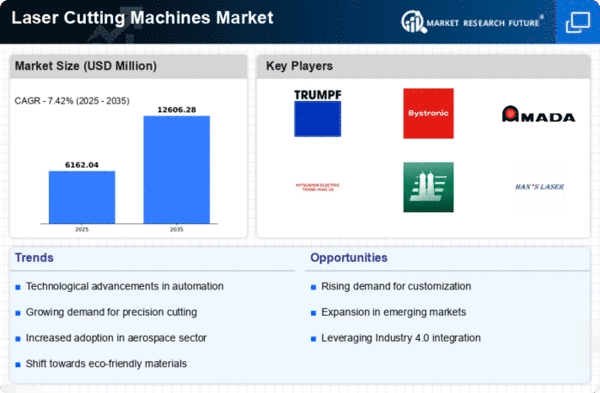

The Laser Cutting Machines Market is experiencing rapid technological advancements that enhance cutting precision and efficiency. Innovations such as fiber laser technology and automation integration are driving the adoption of laser cutting machines across various sectors. For instance, fiber lasers provide higher energy efficiency and lower operational costs compared to traditional CO2 lasers. As a result, manufacturers are increasingly investing in these advanced technologies to improve productivity. The market is projected to reach 5.74 USD Billion in 2024, indicating a robust demand for state-of-the-art Laser Cutting Machines Market solutions.

Growing Demand from Automotive Sector

The automotive industry is a significant driver of the Laser Cutting Machines Industry, as manufacturers seek to improve production efficiency and reduce material waste. Laser cutting machines are utilized for various applications, including cutting body panels and components with intricate designs. The increasing trend towards lightweight materials in vehicle manufacturing further propels the demand for high precision laser cutting technology. As the automotive sector continues to evolve, the market for laser cutting machines is expected to grow, contributing to the projected market value of 12.6 USD Billion by 2035.

Expansion of Metal Fabrication Industry

The metal fabrication industry is a key contributor to the growth of the Laser Cutting Machines Industry. As industries such as construction, shipbuilding, and machinery manufacturing expand, the need for efficient and precise metal cutting solutions becomes paramount. Laser cutting machines offer advantages such as reduced material waste and faster processing times, making them an attractive option for metal fabricators. This trend is expected to bolster the market, as businesses seek to enhance their operational capabilities and meet increasing demand for customized metal products.

Rising Adoption in Aerospace Manufacturing

The aerospace sector is increasingly integrating Laser Cutting Machines Market into its manufacturing processes, thereby influencing the Laser Cutting Machines Industry. The need for high precision and quality in aerospace components necessitates advanced cutting technologies. Laser cutting machines enable manufacturers to achieve intricate designs and tight tolerances, which are critical in aerospace applications. As the aerospace industry expands, the demand for Laser Cutting Machines Market solutions is likely to increase, supporting a compound annual growth rate (CAGR) of 7.44% from 2025 to 2035.

Increased Focus on Automation and Industry 4.0

The Laser Cutting Machines Industry is witnessing a shift towards automation and the principles of Industry 4.0. Manufacturers are increasingly adopting automated Laser Cutting Machines Market that integrate with smart manufacturing processes. This transition allows for enhanced operational efficiency, reduced labor costs, and improved production flexibility. As industries strive to optimize their manufacturing processes, the demand for automated laser cutting solutions is likely to rise. This trend aligns with the projected growth of the market, as companies seek to leverage technology for competitive advantage.