Market Growth Projections

The Global Laser Processing Market Industry is projected to experience substantial growth over the next decade. With a compound annual growth rate (CAGR) of 9.18% anticipated from 2025 to 2035, the market is set to evolve significantly. The increasing adoption of laser technologies across various sectors, including manufacturing, healthcare, and electronics, is driving this growth. As industries seek to enhance efficiency and precision, the demand for laser processing solutions is expected to rise, leading to a market valuation of 67.9 USD Billion by 2035. This growth trajectory indicates a robust future for the laser processing sector.

Technological Advancements

The Global Laser Processing Market Industry is experiencing rapid technological advancements, which are enhancing the efficiency and precision of laser systems. Innovations in laser types, such as fiber lasers and ultrafast lasers, are enabling applications in various sectors, including automotive, aerospace, and electronics. These advancements not only improve processing speeds but also reduce operational costs. For instance, fiber lasers are known for their high efficiency and low maintenance requirements, making them increasingly popular. As a result, the market is projected to reach 25.8 USD Billion in 2024, reflecting the growing demand for advanced laser technologies.

Environmental Considerations

The Global Laser Processing Market Industry is increasingly influenced by environmental considerations, as industries strive to adopt more sustainable practices. Laser processing technologies are known for their minimal environmental impact compared to traditional methods, as they generate less waste and consume less energy. This shift towards eco-friendly manufacturing processes is prompting companies to invest in laser systems that align with sustainability goals. As regulations become stricter and consumers demand greener products, the adoption of laser processing is likely to accelerate, contributing to the market's growth trajectory in the coming years.

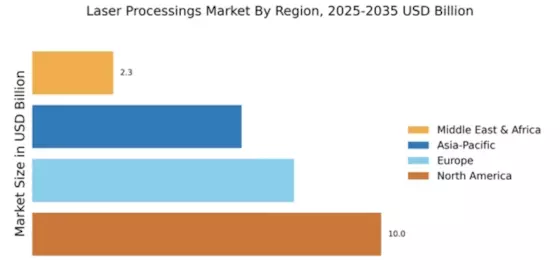

Expansion in Emerging Markets

The Global Laser Processing Market Industry is benefiting from expansion in emerging markets, where industrialization and technological adoption are on the rise. Countries in Asia-Pacific, particularly China and India, are witnessing significant investments in laser technology across various sectors, including textiles, electronics, and automotive. This trend is driven by the need for efficient production methods and the desire to enhance product quality. As these markets continue to develop, the demand for laser processing is expected to increase, further propelling the market's growth and creating new opportunities for manufacturers and suppliers.

Growing Demand in Manufacturing

The Global Laser Processing Market Industry is witnessing a surge in demand from the manufacturing sector, driven by the need for high-quality and precise production processes. Industries such as automotive and electronics are increasingly adopting laser processing for cutting, welding, and engraving applications. This trend is fueled by the advantages of laser technology, including reduced material waste and enhanced product quality. As manufacturers seek to optimize their production lines, the market is expected to grow significantly, with projections indicating a rise to 67.9 USD Billion by 2035. This growth underscores the pivotal role of laser processing in modern manufacturing.

Rising Applications in Healthcare

The Global Laser Processing Market Industry is experiencing a notable increase in applications within the healthcare sector. Laser technologies are being utilized for a range of medical procedures, including surgical applications, diagnostics, and therapeutic treatments. The precision and minimally invasive nature of laser procedures are appealing to healthcare providers and patients alike. As the healthcare industry continues to innovate and adopt advanced technologies, the demand for laser processing is projected to grow. This trend not only enhances patient outcomes but also contributes to the overall expansion of the market.