Regulatory Compliance

Regulatory compliance is becoming increasingly critical for the Acrylic Rubber Market. Governments worldwide are implementing stringent regulations regarding the use of chemicals and materials in various applications. These regulations aim to ensure safety, health, and environmental protection. As a result, manufacturers are compelled to adapt their production processes and formulations to meet these standards. Compliance not only mitigates legal risks but also enhances product credibility and marketability. The market is witnessing a shift towards the development of compliant acrylic rubber products that meet international standards, which could potentially open new avenues for growth. Companies that proactively embrace regulatory changes are likely to gain a competitive edge in the Acrylic Rubber Market.

Sustainability Initiatives

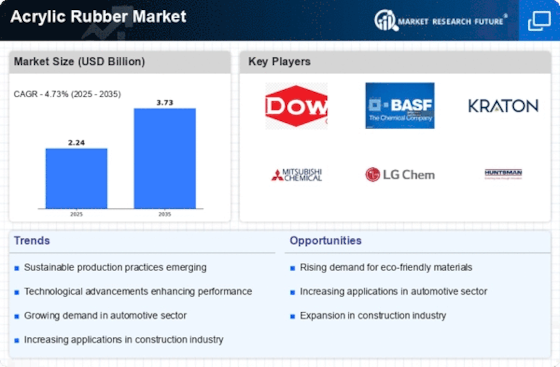

The Acrylic Rubber Market is experiencing a notable shift towards sustainability initiatives. Manufacturers are increasingly focusing on eco-friendly production processes and materials. This trend is driven by rising consumer awareness regarding environmental issues and regulatory pressures aimed at reducing carbon footprints. As a result, companies are investing in research and development to create bio-based acrylic rubbers that minimize environmental impact. The market for sustainable materials is projected to grow significantly, with estimates suggesting a compound annual growth rate of over 5% in the coming years. This shift not only aligns with global sustainability goals but also enhances brand reputation, thereby attracting environmentally conscious consumers. Consequently, the emphasis on sustainability is likely to play a pivotal role in shaping the future of the Acrylic Rubber Market.

Technological Advancements

Technological advancements are profoundly influencing the Acrylic Rubber Market. Innovations in polymer chemistry and manufacturing processes are enabling the production of high-performance acrylic rubbers with enhanced properties. These advancements include improved heat resistance, flexibility, and durability, which are essential for various applications such as automotive, construction, and electronics. The integration of automation and smart manufacturing techniques is also streamlining production, reducing costs, and increasing efficiency. Market data indicates that the adoption of advanced technologies could lead to a reduction in production costs by approximately 10-15%. As manufacturers continue to leverage these technologies, the Acrylic Rubber Market is expected to witness a surge in product offerings, catering to diverse consumer needs and preferences.

Growing Demand in Emerging Markets

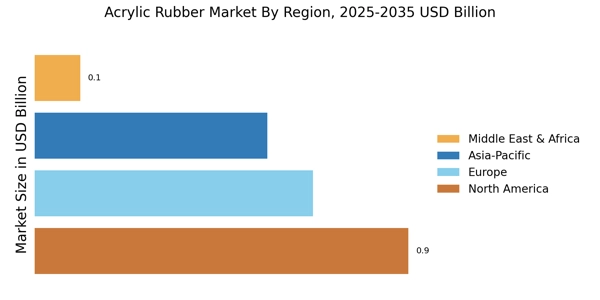

The Acrylic Rubber Market is witnessing a surge in demand from emerging markets, driven by rapid industrialization and urbanization. Countries in Asia-Pacific and Latin America are experiencing significant growth in sectors such as automotive, construction, and consumer goods, which are major consumers of acrylic rubber products. Market analysis suggests that the Asia-Pacific region alone could account for over 40% of the total market share by 2026, reflecting a robust growth trajectory. This increasing demand is further fueled by rising disposable incomes and changing consumer lifestyles, leading to a higher consumption of durable goods. As manufacturers seek to capitalize on these opportunities, the Acrylic Rubber Market is likely to expand its footprint in these regions, fostering economic growth and innovation.

Rising Applications in Automotive Sector

The automotive sector is emerging as a significant driver for the Acrylic Rubber Market. With the increasing demand for lightweight and durable materials, acrylic rubber is being utilized in various automotive applications, including seals, gaskets, and coatings. The shift towards electric vehicles and advanced automotive technologies is further propelling the need for high-performance materials that can withstand extreme conditions. Market projections indicate that the automotive segment could contribute to over 30% of the total acrylic rubber consumption by 2027. This trend is likely to encourage manufacturers to innovate and develop specialized acrylic rubber formulations tailored for automotive applications, thereby enhancing the overall growth prospects of the Acrylic Rubber Market.