North America : Innovation Hub for 3D Printing

North America dominates the 3D Printer Repair and MRO Services Market, holding a significant share of 1.25B in 2025. The region's growth is driven by rapid technological advancements, increasing adoption of 3D printing across various industries, and supportive regulatory frameworks. The demand for efficient repair services is further fueled by the rising number of 3D printers in operation, enhancing the need for maintenance and repair solutions.

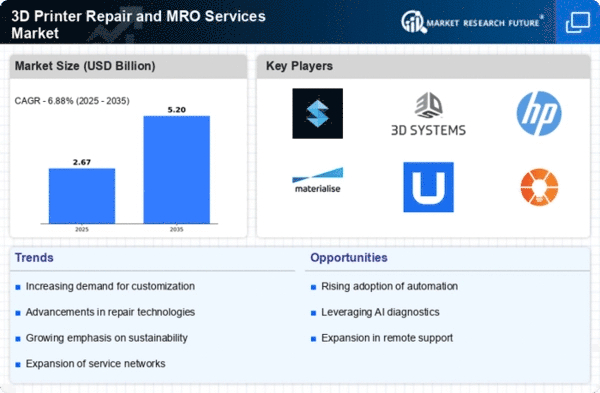

The competitive landscape in North America is robust, featuring key players such as Stratasys, 3D Systems, and HP. These companies are at the forefront of innovation, offering comprehensive repair and maintenance services. The U.S. leads the market, supported by a strong manufacturing base and a growing emphasis on additive manufacturing technologies. This environment fosters collaboration and investment, ensuring sustained growth in the sector.

Europe : Emerging Powerhouse in 3D Printing

Europe's 3D Printer Repair and MRO Services Market is valued at 0.75B in 2025, reflecting a growing demand driven by the increasing adoption of 3D printing technologies across various sectors. The region benefits from strong regulatory support aimed at fostering innovation and sustainability in manufacturing. Initiatives promoting the circular economy are also catalyzing the need for efficient repair services, as companies seek to extend the lifecycle of their 3D printers.

Leading countries in Europe include Germany, France, and the Netherlands, where companies like Materialise and Ultimaker are making significant strides. The competitive landscape is characterized by a mix of established players and emerging startups, all vying for market share. The European market is poised for growth, supported by a collaborative ecosystem that encourages research and development in 3D printing technologies.

Asia-Pacific : Rapidly Growing Market Potential

The Asia-Pacific region is witnessing a burgeoning 3D Printer Repair and MRO Services Market, projected at 0.4B in 2025. This growth is driven by increasing industrialization, a rising number of startups in the 3D printing space, and government initiatives promoting advanced manufacturing technologies. Countries like China and Japan are leading the charge, with significant investments in 3D printing infrastructure and services, enhancing the demand for repair and maintenance solutions.

China stands out as a key player in the region, with numerous local companies entering the market. The competitive landscape is evolving, with both domestic and international firms striving to capture market share. The presence of major global players, such as HP and Formlabs, further intensifies competition, driving innovation and service quality in the region.

Middle East and Africa : Resource-Rich Frontier for 3D Printing

The Middle East and Africa region represents a nascent market for 3D Printer Repair and MRO Services, valued at 0.1B in 2025. The growth in this region is primarily driven by increasing investments in technology and manufacturing sectors, alongside a growing awareness of the benefits of 3D printing. Governments are beginning to recognize the potential of additive manufacturing, leading to initiatives aimed at fostering innovation and attracting foreign investment.

Countries like South Africa and the UAE are emerging as key players in the 3D printing landscape, with local firms beginning to offer repair and maintenance services. The competitive environment is still developing, but the presence of international companies is expected to stimulate growth and enhance service offerings in the region, paving the way for future expansion.