North America : Manufacturing Powerhouse

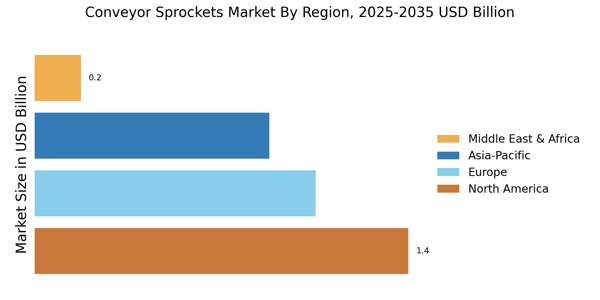

North America is the largest market for conveyor sprockets, holding approximately 40% of the global market share. The region's growth is driven by the booming manufacturing sector, increased automation, and stringent safety regulations. The demand for efficient material handling solutions is rising, particularly in industries such as automotive and food processing, which are heavily reliant on conveyor systems. Regulatory support for advanced manufacturing technologies further catalyzes market expansion.

The United States leads the North American market, with key players like Dodge, Rexnord, and Martin Sprocket & Gear dominating the landscape. The competitive environment is characterized by innovation and strategic partnerships among manufacturers. Canada also contributes significantly, focusing on enhancing its manufacturing capabilities. The presence of established companies ensures a robust supply chain and continuous product development, catering to diverse industrial needs.

Europe : Innovation and Sustainability

Europe is the second-largest market for conveyor sprockets, accounting for around 30% of the global share. The region's growth is propelled by increasing investments in automation and a strong emphasis on sustainability. Regulatory frameworks, such as the EU's Green Deal, encourage the adoption of energy-efficient technologies, driving demand for advanced conveyor systems. The focus on reducing carbon footprints in manufacturing processes further supports market growth.

Germany and the UK are the leading countries in this market, with a strong presence of key players like KTR Systems and Schaeffler. The competitive landscape is marked by innovation, with companies investing in R&D to develop eco-friendly products. The market is also witnessing a trend towards digitalization, with smart conveyor systems gaining traction. This evolution is supported by collaborations between manufacturers and technology providers, enhancing operational efficiency and sustainability.

Asia-Pacific : Emerging Market Dynamics

Asia-Pacific is witnessing significant growth in the conveyor sprockets market, holding approximately 25% of the global share. The region's rapid industrialization, coupled with increasing demand for automation in manufacturing, is driving this expansion. Countries like China and India are at the forefront, with government initiatives promoting infrastructure development and modernization of manufacturing processes. The growing e-commerce sector also fuels demand for efficient logistics solutions, including conveyor systems.

China is the largest market in the region, supported by numerous local manufacturers and international players like Bando Chemical Industries and Tsubaki. The competitive landscape is evolving, with companies focusing on cost-effective solutions and technological advancements. India is emerging as a strong contender, with increasing investments in manufacturing and logistics. The presence of a diverse range of players ensures a dynamic market environment, catering to various industrial needs.

Middle East and Africa : Resource-Rich Opportunities

The Middle East and Africa region is gradually emerging in the conveyor sprockets market, holding about 5% of the global share. The growth is primarily driven by increasing investments in infrastructure and mining sectors, particularly in countries like South Africa and the UAE. The region's focus on diversifying its economy away from oil dependency is leading to enhanced manufacturing capabilities and demand for efficient material handling solutions. Regulatory support for industrial development is also a key factor.

South Africa is the leading market in this region, with a growing number of local manufacturers and international companies establishing a presence. The competitive landscape is characterized by a mix of established players and new entrants, focusing on innovation and cost efficiency. The region's unique challenges, such as logistics and supply chain issues, are being addressed through strategic partnerships and investments in technology, ensuring a sustainable growth trajectory.