Market Trends and Projections

Rising Investment in Aerospace R&D

Rising investment in aerospace research and development (R&D) is a critical driver for the Global Composite Materials and Aluminum Alloys in Aerospace Market Industry. Governments and private entities are increasingly allocating funds to explore innovative materials and technologies that can enhance aircraft performance and safety. This influx of investment supports the development of next-generation composite materials and aluminum alloys, which are essential for advancing aerospace engineering. As a result, the market is poised for growth, with projections indicating a substantial increase in demand for these materials as new aircraft models are introduced and existing fleets are upgraded.

Increasing Focus on Fuel Efficiency

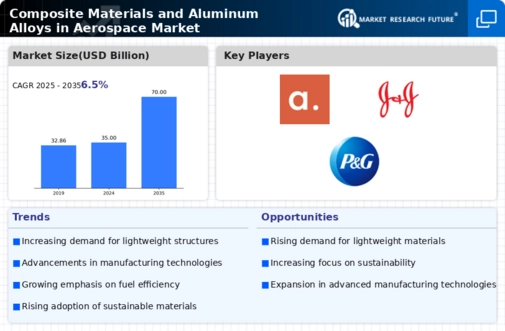

The Global Composite Materials and Aluminum Alloys in Aerospace Market Industry is significantly influenced by the increasing focus on fuel efficiency among aircraft manufacturers. Airlines are under pressure to reduce operational costs and minimize their carbon footprint, prompting the adoption of advanced materials that enhance fuel economy. Composites and aluminum alloys are integral to achieving these goals, as they allow for lighter aircraft designs and improved aerodynamics. This trend is expected to propel the market to an estimated 70 USD Billion by 2035, as manufacturers seek to comply with stringent environmental regulations and consumer demands for greener aviation solutions.

Growing Demand for Lightweight Materials

The Global Composite Materials and Aluminum Alloys in Aerospace Market Industry experiences a notable increase in demand for lightweight materials. This trend is driven by the aerospace sector's need to enhance fuel efficiency and reduce emissions. Lightweight materials, such as composites and aluminum alloys, contribute to significant weight reductions in aircraft, which can lead to lower operational costs. For instance, the integration of composite materials in aircraft structures can reduce weight by up to 20 percent. As a result, the market is projected to reach 35 USD Billion in 2024, reflecting the industry's shift towards sustainable aviation solutions.

Technological Advancements in Material Science

Technological advancements in material science play a pivotal role in shaping the Global Composite Materials and Aluminum Alloys in Aerospace Market Industry. Innovations in manufacturing processes, such as additive manufacturing and advanced composite fabrication techniques, enable the production of high-performance materials with enhanced properties. These advancements not only improve the mechanical performance of aerospace components but also facilitate the development of complex geometries that were previously unattainable. As a result, the market is expected to grow at a CAGR of 6.5% from 2025 to 2035, indicating a robust trajectory driven by ongoing research and development efforts.

Expansion of Aerospace Manufacturing Capabilities

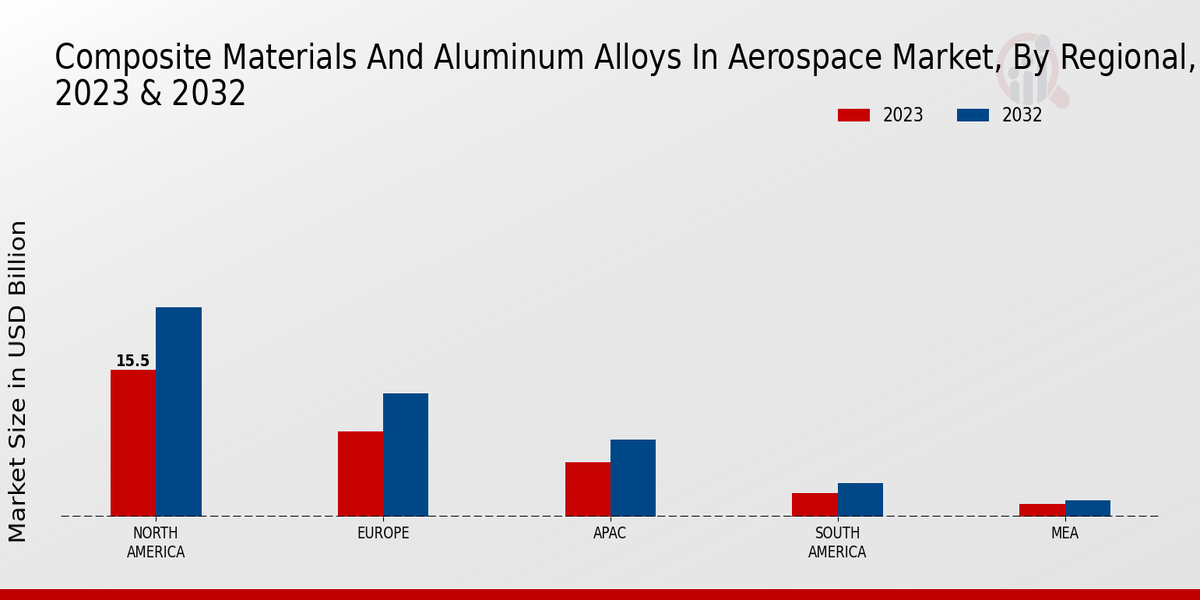

The expansion of aerospace manufacturing capabilities is a significant factor influencing the Global Composite Materials and Aluminum Alloys in Aerospace Market Industry. As countries invest in advanced manufacturing technologies and facilities, the production of composite materials and aluminum alloys becomes more efficient and cost-effective. This expansion enables manufacturers to meet the growing demand for lightweight and high-performance materials in the aerospace sector. Additionally, the establishment of new production facilities in emerging markets contributes to the global supply chain, ensuring that aerospace companies have access to the materials they need to innovate and compete effectively.