Growing Emphasis on Precision and Quality

The Zero Point Clamping System Market is significantly influenced by the growing emphasis on precision and quality in manufacturing. As industries such as aerospace, automotive, and medical devices demand higher accuracy in their production processes, the need for reliable clamping systems becomes paramount. Zero point clamping systems offer enhanced precision by ensuring consistent workpiece positioning, which is critical for high-quality output. Recent studies suggest that manufacturers utilizing these systems report a reduction in scrap rates and improved product quality. This trend is likely to drive further investments in zero point clamping technologies, as companies prioritize quality assurance in their operations. The increasing focus on precision is expected to propel the Zero Point Clamping System Market forward, as more manufacturers recognize the value of investing in advanced clamping solutions.

Technological Advancements in Clamping Systems

Technological advancements play a crucial role in shaping the Zero Point Clamping System Market. Innovations in materials and design have led to the development of more robust and versatile clamping systems. These advancements not only improve the performance of clamping systems but also enhance their adaptability to various machining processes. For instance, the integration of smart technologies, such as IoT and automation, allows for real-time monitoring and adjustments, further optimizing manufacturing operations. As a result, the market is witnessing an influx of new products that cater to diverse industrial needs. The increasing complexity of manufacturing processes necessitates the adoption of these advanced clamping solutions, indicating a strong growth trajectory for the Zero Point Clamping System Market in the coming years.

Increased Focus on Lean Manufacturing Practices

The Zero Point Clamping System Market is benefiting from the increased focus on lean manufacturing practices across various sectors. Lean manufacturing emphasizes the elimination of waste and the optimization of processes, which aligns well with the capabilities of zero point clamping systems. These systems enable manufacturers to achieve faster changeovers and reduce setup times, thereby enhancing overall operational efficiency. As companies strive to implement lean principles, the demand for clamping solutions that support these initiatives is likely to grow. Recent surveys indicate that organizations adopting lean practices report significant improvements in productivity and cost savings. This trend suggests a promising outlook for the Zero Point Clamping System Market, as more manufacturers recognize the advantages of integrating advanced clamping technologies into their lean manufacturing strategies.

Expansion of the Aerospace and Automotive Sectors

The expansion of the aerospace and automotive sectors is a significant driver for the Zero Point Clamping System Market. These industries are characterized by their stringent requirements for precision and efficiency, making them prime candidates for the adoption of advanced clamping technologies. As global demand for air travel and electric vehicles continues to rise, manufacturers are compelled to enhance their production capabilities. The zero point clamping systems facilitate rapid setup changes and ensure high accuracy, which is essential for meeting the rigorous standards of these sectors. Market analysis indicates that the aerospace and automotive industries are expected to contribute substantially to the growth of the clamping system market, with projections suggesting a potential increase in market share by over 15% in the next few years. This trend underscores the importance of the Zero Point Clamping System Market in supporting the evolving needs of these critical sectors.

Rising Demand for Efficient Manufacturing Solutions

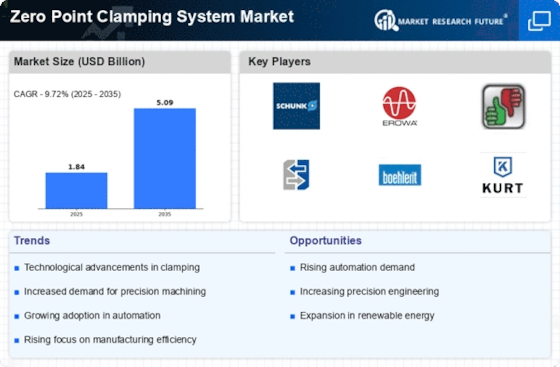

The Zero Point Clamping System Market is experiencing a notable surge in demand for efficient manufacturing solutions. As industries strive to enhance productivity and reduce operational costs, the adoption of advanced clamping systems has become increasingly prevalent. These systems facilitate rapid workpiece changes, thereby minimizing downtime and maximizing throughput. According to recent data, the market for clamping systems is projected to grow at a compound annual growth rate of approximately 7% over the next five years. This growth is driven by the need for manufacturers to remain competitive in a fast-paced environment, where efficiency and speed are paramount. Consequently, the Zero Point Clamping System Market is positioned to benefit significantly from this trend, as companies seek to implement innovative solutions that streamline their manufacturing processes.