Growing Demand for Miniaturized Electronics

The increasing trend towards miniaturization in electronics is a critical driver for the US Underfill Dispensers Market. As consumer electronics, automotive, and medical devices evolve, the need for smaller, more efficient components has surged. This trend necessitates the use of underfill materials to enhance the reliability and performance of compact electronic assemblies. Market data indicates that the demand for underfill dispensers is likely to rise in tandem with the miniaturization trend, with projections suggesting a growth rate of around 5% annually. Manufacturers are thus compelled to adopt advanced underfill dispensing solutions to meet the stringent requirements of miniaturized electronics, further propelling the market's expansion.

Regulatory Compliance and Quality Standards

The US Underfill Dispensers Market is also shaped by stringent regulatory compliance and quality standards imposed on electronic manufacturing processes. As industries face increasing scrutiny regarding product reliability and safety, adherence to quality standards becomes paramount. This has led to a heightened demand for underfill dispensers that can ensure consistent application and meet regulatory requirements. Market analysis reveals that companies investing in compliant dispensing technologies are likely to gain a competitive edge, as they can assure customers of product integrity. The emphasis on quality and compliance is expected to drive the growth of the underfill dispensers market, as manufacturers seek solutions that align with industry standards and enhance their operational credibility.

Increased Focus on Automation in Manufacturing

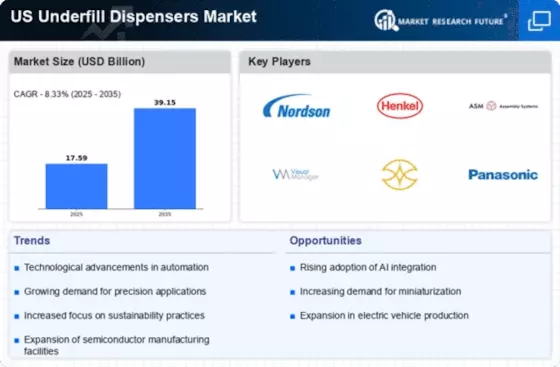

The US Underfill Dispensers Market is significantly influenced by the growing emphasis on automation within manufacturing processes. As companies strive to enhance operational efficiency and reduce labor costs, automated underfill dispensing systems are becoming increasingly prevalent. These systems not only improve the speed and accuracy of the dispensing process but also minimize human error, which is crucial in high-stakes environments such as semiconductor fabrication. Recent statistics suggest that the automation market in manufacturing is expected to grow by approximately 8% annually, indicating a robust demand for automated underfill dispensers. This shift towards automation is likely to drive the adoption of advanced dispensing technologies, thereby fostering growth in the underfill dispensers market.

Rising Demand for High-Performance Electronics

The US Underfill Dispensers Market is witnessing a surge in demand for high-performance electronics, particularly in sectors such as telecommunications and computing. As the performance requirements for electronic devices escalate, manufacturers are increasingly utilizing underfill materials to enhance thermal and mechanical stability. This trend is supported by market data indicating that the high-performance electronics segment is projected to grow at a CAGR of 7% over the next few years. Consequently, the demand for underfill dispensers that can efficiently apply these materials is expected to rise, driving innovation and investment in the market. The focus on high-performance applications is likely to shape the future landscape of the underfill dispensers market.

Technological Advancements in Dispensing Equipment

The US Underfill Dispensers Market is experiencing a notable transformation due to rapid technological advancements in dispensing equipment. Innovations such as precision dispensing systems and enhanced control mechanisms are enabling manufacturers to achieve higher accuracy and efficiency in underfilling processes. This is particularly relevant in sectors like semiconductor manufacturing, where the demand for miniaturized components is escalating. According to recent data, the market for advanced dispensing technologies is projected to grow at a compound annual growth rate (CAGR) of approximately 6% over the next five years. As companies invest in state-of-the-art underfill dispensers, the overall productivity and reliability of electronic assemblies are expected to improve significantly, thereby driving the market forward.