Innovation in Material Science

The Ultra Low Alpha Metal Market is being driven by ongoing innovation in material science. Researchers and manufacturers are continuously exploring new alloys and compositions that enhance the properties of ultra low alpha metals, making them more suitable for a wider range of applications. Innovations such as improved manufacturing techniques and enhanced material properties are likely to expand the market reach of ultra low alpha metals. As industries seek to improve performance and reduce costs, the demand for innovative materials is expected to grow. This trend indicates a dynamic future for the Ultra Low Alpha Metal Market, as advancements in material science pave the way for new opportunities.

Regulatory Compliance and Standards

The Ultra Low Alpha Metal Market is shaped by stringent regulatory compliance and standards that govern the use of materials in various applications. Industries such as aerospace and healthcare are subject to rigorous regulations regarding radiation emissions, which necessitate the use of ultra low alpha metals. Compliance with these standards not only ensures safety but also enhances product reliability, thereby increasing the demand for these specialized materials. As regulations evolve, manufacturers are likely to invest more in ultra low alpha metals to meet compliance requirements. This trend indicates a sustained growth potential for the Ultra Low Alpha Metal Market as industries adapt to changing regulatory landscapes.

Increasing Applications in Aerospace

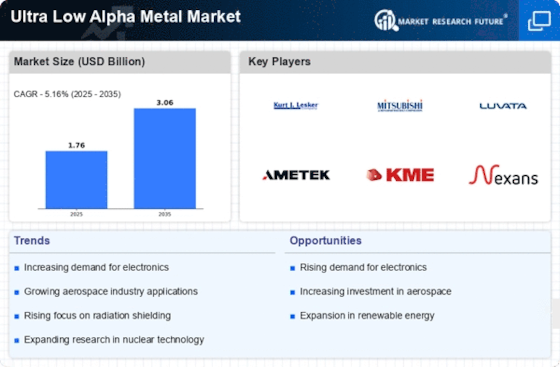

The Ultra Low Alpha Metal Market is experiencing a surge in demand due to its increasing applications in the aerospace sector. As aerospace manufacturers seek materials that minimize radiation emissions, ultra low alpha metals are becoming essential for components in satellites and spacecraft. The unique properties of these metals, such as their low alpha particle emissions, make them ideal for sensitive electronic equipment used in space. According to recent data, the aerospace industry is projected to grow at a compound annual growth rate of 4.5% over the next five years, further driving the demand for ultra low alpha metals. This trend indicates a robust market potential for suppliers and manufacturers within the Ultra Low Alpha Metal Market.

Growth in Medical Device Manufacturing

The Ultra Low Alpha Metal Market is significantly influenced by the growth in medical device manufacturing. As the healthcare sector increasingly relies on advanced technologies, the demand for materials that ensure safety and reliability in medical devices is paramount. Ultra low alpha metals are particularly valued in applications such as radiation therapy equipment and diagnostic imaging devices, where minimizing radiation exposure is critical. Recent statistics suggest that the medical device market is expected to reach USD 600 billion by 2025, which could lead to a substantial increase in the consumption of ultra low alpha metals. This growth trajectory presents a promising opportunity for stakeholders in the Ultra Low Alpha Metal Market.

Emerging Markets and Economic Development

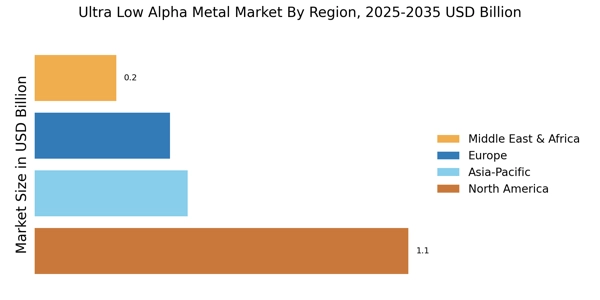

The Ultra Low Alpha Metal Market is poised for growth as emerging markets experience economic development and industrialization. Countries investing in advanced manufacturing and technology sectors are increasingly adopting ultra low alpha metals for their unique properties. As these markets expand, the demand for high-performance materials in electronics, aerospace, and medical applications is expected to rise. Recent analyses indicate that regions such as Asia-Pacific are witnessing rapid industrial growth, which could lead to a significant increase in the consumption of ultra low alpha metals. This trend suggests that the Ultra Low Alpha Metal Market may benefit from the economic advancements in these regions.