Customization Demand in Twister Winder Market

The demand for customization is significantly influencing the Twister Winder Market. As end-users seek tailored solutions to meet specific production requirements, manufacturers are compelled to innovate and offer customizable winding solutions. This trend is particularly evident in sectors such as textiles and composites, where unique winding patterns and specifications are essential. Market data suggests that the customization segment is expected to grow at a compound annual growth rate of 15% over the next five years. This shift not only enhances customer satisfaction but also allows manufacturers to differentiate their offerings in a competitive landscape. Consequently, the ability to provide customized solutions is becoming a critical driver for success in the Twister Winder Market.

Sustainability Initiatives in Twister Winder Market

Sustainability initiatives are becoming increasingly pivotal within the Twister Winder Market. Manufacturers are under pressure to adopt eco-friendly practices, which include utilizing sustainable materials and reducing waste during the winding process. The implementation of energy-efficient machinery not only aligns with environmental goals but also offers cost savings in the long run. Recent studies indicate that companies focusing on sustainability are likely to see a 20% increase in customer loyalty. Additionally, regulatory frameworks are evolving, pushing for greener production methods. As a result, the Twister Winder Market is witnessing a shift towards sustainable practices, which could redefine competitive dynamics and open new avenues for growth.

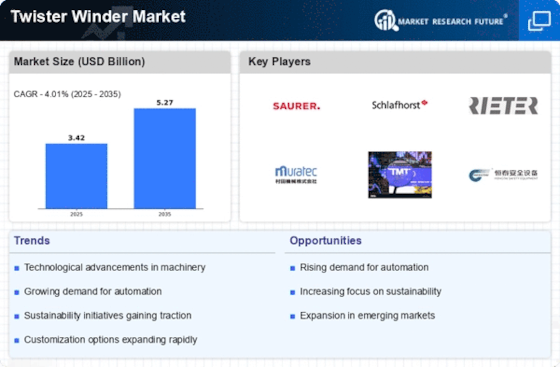

Technological Advancements in Twister Winder Market

The Twister Winder Market is experiencing a notable transformation due to rapid technological advancements. Innovations in automation and control systems are enhancing the efficiency and precision of twister winders. For instance, the integration of IoT technology allows for real-time monitoring and predictive maintenance, which can reduce downtime and operational costs. According to recent data, the adoption of advanced winding technologies is projected to increase productivity by up to 30%. Furthermore, the development of energy-efficient models is likely to appeal to manufacturers aiming to reduce their carbon footprint. As these technologies continue to evolve, they are expected to drive significant growth in the Twister Winder Market, attracting investments and fostering competitive advantages among key players.

Rising Demand from Textile Industry in Twister Winder Market

The Twister Winder Market is witnessing a surge in demand driven by the textile sector. As the global textile industry expands, the need for efficient winding solutions becomes paramount. Twister winders play a crucial role in producing high-quality yarns, which are essential for various textile applications. Recent statistics indicate that the textile industry is projected to grow at a rate of 4% annually, thereby increasing the demand for twister winders. This growth is further fueled by the rising popularity of technical textiles, which require specialized winding techniques. As a result, manufacturers in the Twister Winder Market are likely to benefit from this upward trend, positioning themselves to meet the evolving needs of the textile sector.

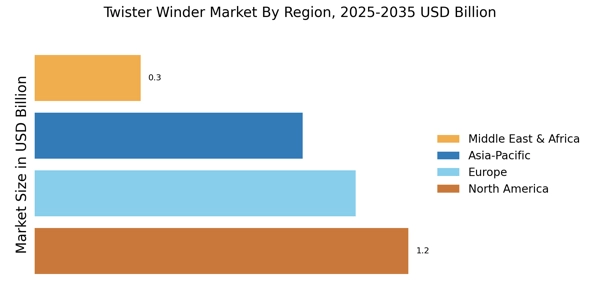

Emerging Markets and Economic Growth in Twister Winder Market

Emerging markets are becoming increasingly relevant to the Twister Winder Market, driven by economic growth and industrialization. Countries in Asia and Africa are witnessing a rise in manufacturing capabilities, leading to heightened demand for advanced winding technologies. As these regions develop, the need for efficient production processes becomes critical, thereby boosting the adoption of twister winders. Market analysis suggests that the growth rate in these emerging economies could reach 10% over the next few years. This trend presents a significant opportunity for manufacturers to expand their reach and establish a foothold in new markets. Consequently, the Twister Winder Market is likely to experience a shift in dynamics as it adapts to the demands of these burgeoning economies.