Rising Demand for Personalized Medicine

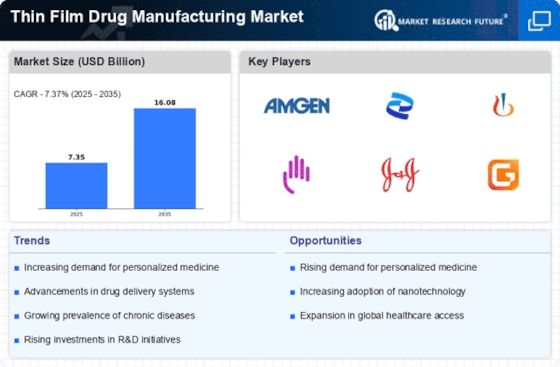

The increasing focus on personalized medicine is emerging as a crucial driver for the Thin Film Drug Manufacturing Market. As healthcare shifts towards tailored treatment approaches, the need for drug delivery systems that can accommodate individual patient profiles is becoming more pronounced. Thin film technologies offer the flexibility to customize dosages and formulations based on specific patient needs, thereby enhancing therapeutic efficacy. The market for personalized medicine is projected to reach USD 2 trillion by 2030, indicating a substantial opportunity for the Thin Film Drug Manufacturing Market. This trend suggests that manufacturers who can adapt their offerings to meet the demands of personalized medicine will likely gain a competitive edge in the evolving pharmaceutical landscape.

Increasing Prevalence of Chronic Diseases

The rising incidence of chronic diseases such as diabetes, cardiovascular disorders, and respiratory ailments is a pivotal driver for the Thin Film Drug Manufacturing Market. As these conditions necessitate long-term medication, the demand for innovative drug delivery systems is surging. Thin film technologies offer advantages such as improved bioavailability and patient compliance, which are crucial for managing chronic conditions. According to recent estimates, the prevalence of diabetes alone is projected to reach 700 million by 2045, thereby amplifying the need for effective drug delivery solutions. This trend indicates a robust growth trajectory for the Thin Film Drug Manufacturing Market, as pharmaceutical companies increasingly invest in developing thin film formulations to cater to this expanding patient population.

Advancements in Drug Delivery Technologies

Technological innovations in drug delivery systems are significantly influencing the Thin Film Drug Manufacturing Market. The advent of nanotechnology, microencapsulation, and other advanced manufacturing techniques has enhanced the efficacy and safety of thin film drugs. These advancements facilitate targeted delivery, reducing side effects and improving therapeutic outcomes. For instance, the integration of smart polymers in thin film formulations allows for controlled release mechanisms, which are becoming increasingly popular in the pharmaceutical sector. The market for drug delivery technologies is expected to grow at a compound annual growth rate of over 10% in the coming years, indicating a favorable environment for the Thin Film Drug Manufacturing Market. As a result, manufacturers are likely to focus on research and development to leverage these technological advancements.

Regulatory Support for Innovative Drug Delivery Systems

Regulatory bodies are increasingly recognizing the importance of innovative drug delivery systems, which is beneficial for the Thin Film Drug Manufacturing Market. Initiatives aimed at expediting the approval process for novel drug formulations are being implemented, encouraging pharmaceutical companies to invest in thin film technologies. For example, the FDA has established pathways for the expedited review of new drug applications that utilize advanced delivery methods. This regulatory support not only fosters innovation but also enhances market entry for new products. As a result, the Thin Film Drug Manufacturing Market is likely to witness an influx of new entrants and products, further stimulating competition and growth. The favorable regulatory landscape is expected to contribute to a more dynamic market environment.

Growing Preference for Non-Invasive Drug Delivery Methods

The shift towards non-invasive drug delivery methods is a significant driver for the Thin Film Drug Manufacturing Market. Patients increasingly prefer alternatives to traditional injections and oral medications, which can be uncomfortable or inconvenient. Thin film formulations, such as sublingual and buccal films, provide a user-friendly approach that enhances patient adherence to treatment regimens. This trend is particularly evident in the management of pain and anxiety disorders, where rapid onset of action is crucial. Market analysis suggests that the demand for non-invasive delivery systems is expected to rise, with a projected market size of over USD 30 billion by 2027. This growing preference underscores the potential for the Thin Film Drug Manufacturing Market to expand its offerings in response to evolving patient needs.

Leave a Comment