North America : Market Leader in Maintenance Services

North America is poised to maintain its leadership in the Textile Machinery Maintenance Services market, holding a significant share of 3.0 in 2025. The region's growth is driven by advanced manufacturing technologies, increasing automation, and a strong focus on sustainability. Regulatory support for innovation and efficiency in textile production further fuels demand for maintenance services, ensuring optimal machinery performance and reduced downtime.

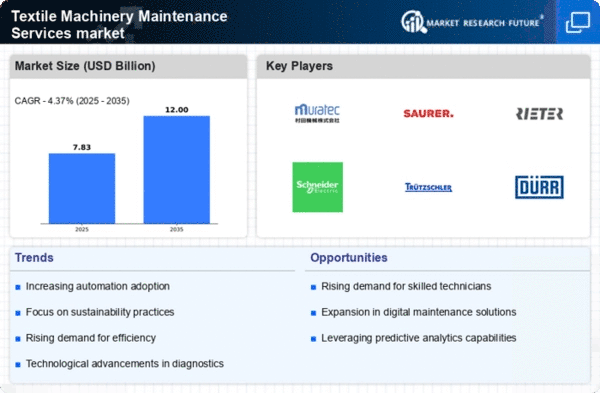

The United States and Canada are the leading countries in this sector, with a competitive landscape featuring key players like Muratec, Schneider, and Rieter. These companies are investing in R&D to enhance service offerings and meet the evolving needs of the textile industry. The presence of established firms and a robust supply chain contribute to the region's market strength, making it a hub for textile machinery maintenance services.

Europe : Innovation and Sustainability Focus

Europe's Textile Machinery Maintenance Services market is projected to reach a size of 2.5 by 2025, driven by a strong emphasis on innovation and sustainability. The region's regulatory frameworks encourage eco-friendly practices, which in turn boost demand for efficient maintenance services. As manufacturers seek to optimize their operations, the need for regular maintenance and upgrades becomes critical, ensuring compliance with stringent environmental standards.

Germany, Switzerland, and Italy are at the forefront of this market, with companies like Saurer, Rieter, and Itema leading the charge. The competitive landscape is characterized by a mix of established players and emerging firms, all striving to enhance service quality and technological capabilities. The focus on digitalization and smart manufacturing is reshaping the industry, making maintenance services more integral to operational success.

Asia-Pacific : Emerging Market with Growth Potential

The Asia-Pacific region is witnessing rapid growth in the Textile Machinery Maintenance Services market, projected to reach 1.8 by 2025. This growth is fueled by increasing industrialization, rising textile production, and a growing emphasis on machinery efficiency. Countries in this region are investing heavily in modernizing their textile industries, which necessitates regular maintenance services to ensure optimal performance and compliance with international standards.

China and India are the leading countries in this market, with a competitive landscape that includes both local and international players. Companies like Picanol and Trützschler are expanding their presence, focusing on service quality and technological advancements. The region's diverse market dynamics and increasing demand for high-quality textile products are driving the need for specialized maintenance services, positioning Asia-Pacific as a key player in the global market.

Middle East and Africa : Emerging Market with Challenges

The Middle East and Africa region is currently the smallest market for Textile Machinery Maintenance Services, with a projected size of 0.2 by 2025. The growth in this region is hindered by economic challenges, limited industrialization, and a lack of investment in advanced textile technologies. However, there is a growing awareness of the importance of maintenance services to enhance machinery efficiency and reduce operational costs, which could drive future demand.

Countries like South Africa and Egypt are beginning to invest in their textile sectors, but the competitive landscape remains underdeveloped compared to other regions. Local players are emerging, but the presence of major international companies is limited. As the region seeks to modernize its textile industry, the demand for maintenance services is expected to gradually increase, albeit at a slower pace than in other regions.