Growth in End-User Industries

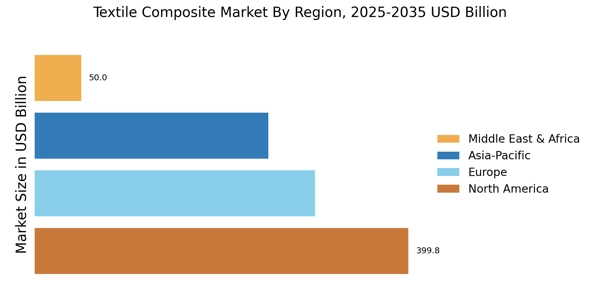

The Textile Composite Market is significantly influenced by the expansion of end-user industries such as automotive, construction, and sports equipment. The automotive sector, in particular, is projected to witness a compound annual growth rate of approximately 5%, leading to increased utilization of textile composites for interior and exterior applications. In construction, the demand for durable and lightweight materials is rising, as textile composites offer enhanced strength and flexibility. Furthermore, the sports equipment industry is increasingly incorporating these materials to improve performance and reduce weight. This diversification across various sectors suggests a promising outlook for the Textile Composite Market, as it adapts to the evolving needs of diverse applications.

Increased Focus on Sustainability

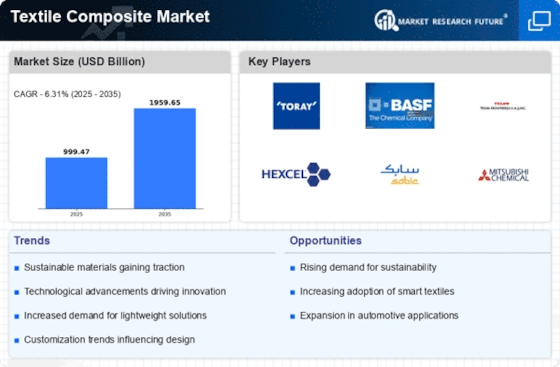

Sustainability is becoming a pivotal driver in the Textile Composite Market, as consumers and manufacturers alike prioritize eco-friendly materials. The shift towards sustainable practices is evident in the growing demand for bio-based and recycled textile composites. For example, the market for recycled textile composites is expected to grow at a rate of 7% annually, reflecting a broader trend towards circular economy principles. Manufacturers are increasingly investing in sustainable sourcing and production methods to meet consumer expectations and regulatory requirements. This focus on sustainability not only enhances brand reputation but also opens new avenues for innovation within the Textile Composite Market, suggesting a transformative impact on future growth.

Integration of Smart Technologies

The integration of smart technologies into textile composites is emerging as a key driver for the Textile Composite Market. Smart textiles, which incorporate sensors and electronics, are gaining traction in various applications, including healthcare, sports, and fashion. The market for smart textiles is projected to grow significantly, with estimates suggesting a compound annual growth rate of over 20%. This growth is fueled by advancements in materials science and the increasing demand for interactive and responsive textiles. As manufacturers explore the potential of smart textile composites, the market is likely to witness innovative products that enhance functionality and user experience, indicating a promising future for the Textile Composite Market.

Rising Demand for Lightweight Materials

The Textile Composite Market experiences a notable increase in demand for lightweight materials across various sectors, including automotive and aerospace. This trend is driven by the need for improved fuel efficiency and performance. For instance, the automotive sector is increasingly adopting textile composites to reduce vehicle weight, which can enhance fuel economy by up to 10%. Additionally, the aerospace industry is utilizing these materials to achieve significant weight reductions, thereby improving overall aircraft efficiency. As manufacturers seek to meet stringent regulations regarding emissions and fuel consumption, the adoption of lightweight textile composites is likely to accelerate, indicating a robust growth trajectory for the Textile Composite Market.

Advancements in Manufacturing Technologies

Innovations in manufacturing technologies are reshaping the Textile Composite Market, enabling the production of more complex and high-performance materials. Techniques such as 3D printing and automated fiber placement are gaining traction, allowing for the creation of intricate designs that were previously unattainable. These advancements not only enhance the performance characteristics of textile composites but also reduce production costs and time. As manufacturers adopt these cutting-edge technologies, the market is likely to see an influx of new products that cater to specific applications, thereby expanding the overall market potential. The ongoing evolution in manufacturing processes indicates a dynamic future for the Textile Composite Market.