Increased Focus on Patient Safety

Patient safety remains a top priority in healthcare, significantly impacting the Sterile Tubing Welder Market. The rising awareness of infection control and the need for sterile environments in medical procedures drive the demand for advanced welding technologies. Sterile tubing welders provide a reliable solution for creating secure and sterile connections, which is essential in various medical applications, including drug delivery systems and surgical procedures. As healthcare facilities increasingly adopt stringent safety protocols, the Sterile Tubing Welder Market is likely to witness substantial growth. The emphasis on minimizing contamination risks aligns with the broader trends in healthcare quality improvement.

Rising Demand for Biopharmaceuticals

The Sterile Tubing Welder Market is experiencing a notable surge in demand due to the increasing production of biopharmaceuticals. As the biopharmaceutical sector expands, the need for sterile and contamination-free processes becomes paramount. This trend is driven by the growing prevalence of chronic diseases and the need for innovative therapies. According to industry reports, the biopharmaceutical market is projected to reach USD 500 billion by 2026, which directly influences the Sterile Tubing Welder Market. The ability of sterile tubing welders to ensure aseptic connections in biopharmaceutical manufacturing processes is critical, thereby enhancing their adoption in the industry.

Growing Adoption of Single-Use Systems

The Sterile Tubing Welder Market is witnessing a shift towards single-use systems in various applications, particularly in bioprocessing and pharmaceutical manufacturing. Single-use technologies offer numerous advantages, including reduced risk of cross-contamination and lower cleaning requirements. This trend is driven by the need for greater flexibility and efficiency in production processes. As companies increasingly adopt single-use systems, the demand for sterile tubing welders that can accommodate these technologies is likely to rise. The market for single-use bioprocessing systems is projected to grow significantly, further propelling the Sterile Tubing Welder Market. This shift reflects a broader movement towards more efficient and cost-effective manufacturing solutions.

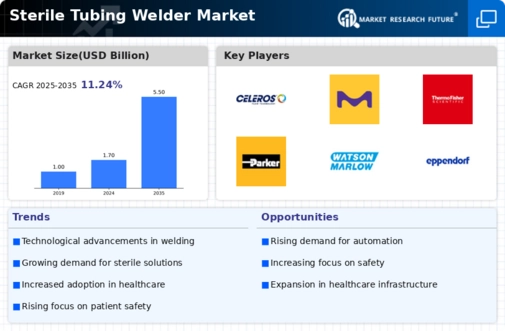

Technological Innovations in Welding Equipment

Technological advancements play a crucial role in shaping the Sterile Tubing Welder Market. Innovations such as automated welding systems and real-time monitoring capabilities enhance the efficiency and reliability of sterile welding processes. These advancements not only improve the quality of welds but also reduce operational costs for manufacturers. The integration of smart technologies, including IoT and AI, into welding equipment is expected to drive market growth. As manufacturers seek to optimize production processes and ensure compliance with stringent regulatory standards, the Sterile Tubing Welder Market is poised for significant transformation. The adoption of these technologies may lead to increased productivity and reduced downtime.

Regulatory Pressures and Compliance Requirements

The Sterile Tubing Welder Market is significantly influenced by regulatory pressures and compliance requirements imposed by health authorities. Stringent regulations regarding product safety and quality assurance necessitate the use of reliable welding technologies in the manufacturing of medical devices and pharmaceuticals. Compliance with these regulations is essential for market players to maintain their competitive edge. As regulatory bodies continue to enforce rigorous standards, the demand for sterile tubing welders that meet these requirements is expected to increase. This trend underscores the importance of investing in advanced welding technologies to ensure compliance and enhance product integrity within the Sterile Tubing Welder Market.