Technological Innovations

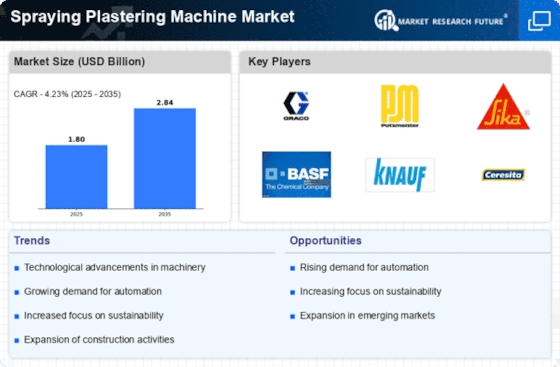

The Spraying Plastering Machine Market is being propelled by continuous technological innovations that enhance the performance and efficiency of plastering machines. Recent advancements include the development of smart machines equipped with sensors and automation features that optimize the plastering process. These innovations not only improve application speed but also reduce material waste, contributing to cost savings for contractors. In 2025, the market is expected to see a rise in the adoption of such advanced technologies, as construction companies seek to leverage the benefits of automation. The integration of digital tools for monitoring and controlling plastering operations is likely to further streamline workflows, making spraying plastering machines indispensable in the industry. As a result, the focus on technological advancements is anticipated to significantly influence the growth trajectory of the Spraying Plastering Machine Market.

Rising Construction Activities

The Spraying Plastering Machine Market is experiencing a surge in demand due to the increasing number of construction projects worldwide. As urbanization accelerates, the need for efficient plastering solutions becomes paramount. In 2025, the construction sector is projected to grow at a compound annual growth rate of approximately 5.5%, driving the adoption of advanced plastering technologies. This growth is fueled by both residential and commercial developments, which require high-quality finishes that spraying plastering machines can provide. Furthermore, the trend towards faster project completion times necessitates the use of mechanized solutions, thereby enhancing productivity and reducing labor costs. Consequently, the rising construction activities are likely to propel the Spraying Plastering Machine Market forward, as stakeholders seek to optimize their operations and meet the demands of modern construction.

Labor Shortages in Construction

The Spraying Plastering Machine Market is significantly influenced by the ongoing labor shortages in the construction sector. As skilled labor becomes increasingly scarce, construction companies are compelled to adopt mechanized solutions to maintain productivity levels. The use of spraying plastering machines not only mitigates the impact of labor shortages but also enhances the quality and consistency of plaster applications. In 2025, it is estimated that labor shortages could lead to project delays, prompting contractors to invest in automated plastering technologies. This shift towards mechanization is expected to drive the growth of the Spraying Plastering Machine Market, as companies seek to streamline their operations and reduce dependency on manual labor. The integration of these machines into construction processes may also lead to improved safety standards, further encouraging their adoption.

Increased Focus on Quality Finishes

The Spraying Plastering Machine Market is witnessing a heightened emphasis on quality finishes in construction projects. As clients demand superior aesthetics and durability, contractors are turning to advanced plastering solutions that can deliver consistent results. Spraying plastering machines offer precision and efficiency, ensuring that surfaces are uniformly coated and free from imperfections. In 2025, the market for high-quality finishes is expected to expand, with a projected growth rate of around 6% annually. This trend is likely to drive the adoption of spraying plastering machines, as they enable contractors to meet stringent quality standards while reducing application time. Additionally, the ability to achieve intricate designs and textures with these machines further enhances their appeal in the Spraying Plastering Machine Market, positioning them as essential tools for modern construction.

Sustainability and Eco-Friendly Solutions

The Spraying Plastering Machine Market is increasingly aligning with sustainability trends as construction practices evolve towards eco-friendly solutions. The demand for environmentally responsible materials and processes is driving the development of plastering machines that utilize sustainable materials and reduce energy consumption. In 2025, the market is projected to witness a shift towards machines that incorporate green technologies, such as low-VOC (volatile organic compounds) materials and energy-efficient operations. This focus on sustainability not only meets regulatory requirements but also appeals to environmentally conscious consumers. As a result, the Spraying Plastering Machine Market is likely to benefit from the growing preference for eco-friendly construction practices, positioning these machines as vital components in achieving sustainable building goals.