Rising Demand in Construction Sector

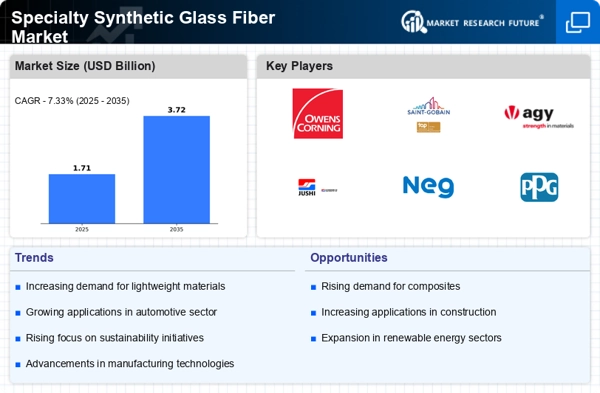

The Specialty Synthetic Glass Fiber Market is experiencing a notable surge in demand, particularly from the construction sector. This increase is attributed to the material's superior strength-to-weight ratio and resistance to environmental degradation. As urbanization accelerates, the need for durable and lightweight construction materials becomes paramount. Reports indicate that the construction industry is projected to grow at a compound annual growth rate of approximately 5% over the next few years, further driving the demand for specialty synthetic glass fibers. These fibers are increasingly utilized in concrete reinforcement, insulation, and other applications, enhancing the overall performance and longevity of construction projects. Consequently, the Specialty Synthetic Glass Fiber Market is poised to benefit significantly from this trend, as builders and architects seek innovative solutions to meet modern construction challenges.

Growing Applications in Renewable Energy

The Specialty Synthetic Glass Fiber Market is witnessing a growing interest in applications related to renewable energy. As the world shifts towards sustainable energy solutions, materials that can withstand harsh environmental conditions are in high demand. Specialty synthetic glass fibers are increasingly utilized in wind turbine blades and solar panel components due to their excellent mechanical properties and resistance to corrosion. The renewable energy sector is anticipated to expand significantly, with investments projected to reach trillions of dollars in the coming years. This growth is likely to drive the demand for specialty synthetic glass fibers, as manufacturers seek materials that enhance the efficiency and durability of renewable energy systems. Consequently, the Specialty Synthetic Glass Fiber Market stands to gain from this trend, as it aligns with the global push for sustainable energy solutions.

Increased Focus on Lightweight Materials

The trend towards lightweight materials is significantly influencing the Specialty Synthetic Glass Fiber Market. Industries such as automotive and aerospace are increasingly prioritizing weight reduction to enhance fuel efficiency and performance. Specialty synthetic glass fibers offer an attractive solution due to their lightweight nature combined with high strength and durability. For example, the automotive sector is projected to see a shift towards using these fibers in vehicle components, potentially reducing overall vehicle weight by up to 20%. This shift not only contributes to improved fuel economy but also aligns with regulatory pressures for lower emissions. As manufacturers seek to innovate and comply with environmental standards, the demand for specialty synthetic glass fibers is expected to rise, further solidifying their role in the Specialty Synthetic Glass Fiber Market.

Regulatory Support for Advanced Materials

The Specialty Synthetic Glass Fiber Market is benefiting from increasing regulatory support aimed at promoting advanced materials. Governments are implementing policies that encourage the use of high-performance materials in various applications, particularly in construction and manufacturing. These regulations often focus on enhancing safety, sustainability, and energy efficiency. For instance, initiatives aimed at reducing carbon footprints are driving industries to adopt materials that offer better performance with lower environmental impact. Specialty synthetic glass fibers, known for their durability and lightweight characteristics, are well-positioned to meet these regulatory demands. As industries adapt to comply with new standards, the Specialty Synthetic Glass Fiber Market is likely to experience a boost in demand, as manufacturers seek compliant materials that also provide competitive advantages.

Advancements in Manufacturing Technologies

Technological innovations in the production of specialty synthetic glass fibers are reshaping the Specialty Synthetic Glass Fiber Market. Enhanced manufacturing processes, such as advanced weaving techniques and improved resin formulations, are leading to the creation of fibers with superior properties. These advancements not only improve the mechanical performance of the fibers but also reduce production costs, making them more accessible to various industries. For instance, the introduction of automated production lines has increased efficiency and consistency in fiber quality. As a result, manufacturers are better positioned to meet the growing demand from sectors such as automotive, aerospace, and electronics, where high-performance materials are essential. The ongoing evolution of manufacturing technologies is likely to play a crucial role in the future growth of the Specialty Synthetic Glass Fiber Market.