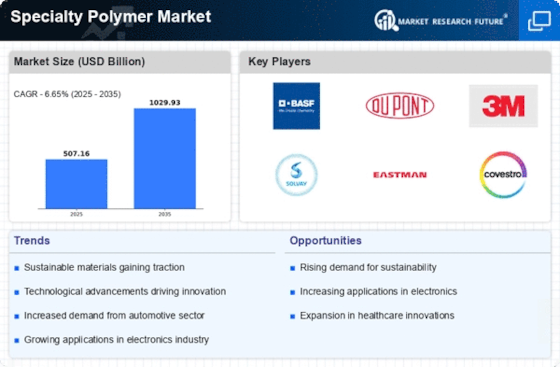

Rising Demand in Automotive Sector

The Specialty Polymer Market is experiencing a notable surge in demand from the automotive sector. As manufacturers increasingly prioritize lightweight materials to enhance fuel efficiency and reduce emissions, specialty polymers are becoming essential. These materials offer superior strength-to-weight ratios, which are critical in vehicle design. In 2025, the automotive industry is projected to account for approximately 25% of the specialty polymer market, driven by innovations in electric vehicles and advanced composites. The shift towards electric mobility necessitates the use of high-performance polymers that can withstand extreme conditions while maintaining structural integrity. This trend indicates a robust growth trajectory for the specialty polymer market, as automotive manufacturers seek to meet stringent regulatory standards and consumer expectations for sustainability.

Increased Focus on Healthcare Innovations

The Specialty Polymer Market is significantly influenced by the rising focus on healthcare innovations. Specialty polymers are increasingly utilized in medical devices, drug delivery systems, and biocompatible materials. The demand for advanced medical technologies is driving the need for polymers that can meet stringent regulatory requirements while providing enhanced performance. In 2025, the healthcare sector is projected to account for about 20% of the specialty polymer market, as the industry seeks materials that offer improved safety and efficacy. Innovations in polymer chemistry are enabling the development of smart polymers that can respond to biological stimuli, further expanding their applications in personalized medicine. This trend suggests a promising future for specialty polymers in the healthcare domain, as they play a crucial role in advancing medical technology.

Sustainability and Eco-Friendly Materials

The Specialty Polymer Market is increasingly shaped by the demand for sustainability and eco-friendly materials. As environmental concerns gain prominence, manufacturers are seeking polymers that are not only high-performing but also sustainable. Biodegradable and bio-based specialty polymers are gaining traction, as they offer a viable alternative to traditional petroleum-based materials. In 2025, the market for sustainable specialty polymers is expected to grow by approximately 15%, driven by regulatory pressures and consumer preferences for environmentally friendly products. This shift towards sustainability is prompting innovation in polymer production processes, leading to the development of materials that minimize environmental impact. Consequently, the specialty polymer market is likely to evolve, with a greater emphasis on sustainable practices and products.

Advancements in Manufacturing Technologies

The Specialty Polymer Market is benefiting from advancements in manufacturing technologies that enhance production efficiency and material performance. Innovations such as 3D printing and advanced extrusion techniques are enabling the creation of complex polymer structures with tailored properties. These technologies allow for rapid prototyping and customization, which are increasingly important in various applications, including aerospace and consumer goods. In 2025, the impact of these advancements is expected to contribute to a market growth rate of around 7%. As manufacturers adopt these cutting-edge technologies, the specialty polymer market is likely to see an influx of new products that meet diverse consumer needs. This trend indicates a dynamic landscape where innovation drives competitiveness and market expansion.

Growth in Electronics and Electrical Applications

The Specialty Polymer Market is witnessing significant growth due to the increasing applications in the electronics and electrical sectors. With the proliferation of smart devices and the Internet of Things, there is a heightened demand for materials that offer excellent electrical insulation and thermal stability. Specialty polymers, such as polyimides and fluoropolymers, are being utilized in the production of circuit boards, connectors, and other critical components. In 2025, the electronics sector is expected to represent around 30% of the specialty polymer market, reflecting a compound annual growth rate of approximately 6%. This growth is fueled by the need for miniaturization and enhanced performance in electronic devices, which positions specialty polymers as vital materials in the ongoing technological evolution.