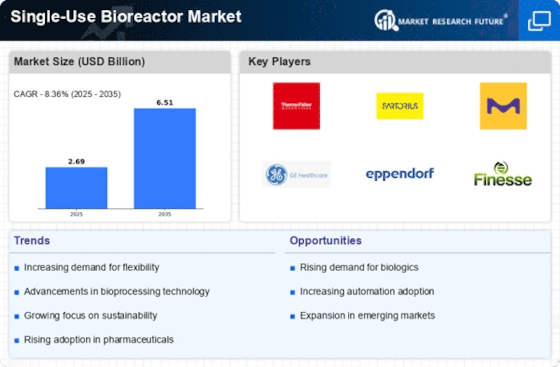

Rising Demand for Biologics

The Single-Use Bioreactor Market is experiencing a notable surge in demand for biologics, driven by the increasing prevalence of chronic diseases and the need for innovative therapies. Biologics, which include monoclonal antibodies and vaccines, require efficient production processes. Single-use bioreactors offer a flexible and cost-effective solution for manufacturers, allowing for rapid scale-up and reduced contamination risks. According to recent data, the biologics market is projected to reach USD 500 billion by 2026, indicating a robust growth trajectory. This trend is likely to propel the Single-Use Bioreactor Market, as companies seek to enhance their production capabilities to meet the rising demand for biologics.

Regulatory Support and Compliance

The Single-Use Bioreactor Market benefits from increasing regulatory support aimed at streamlining the approval processes for biopharmaceutical products. Regulatory bodies are recognizing the advantages of single-use technologies in terms of safety and efficiency. This support is crucial as it encourages manufacturers to adopt single-use systems, which are often viewed as compliant with current Good Manufacturing Practices (cGMP). The alignment of single-use bioreactors with regulatory standards not only enhances product quality but also fosters innovation in bioprocessing. As regulatory frameworks continue to evolve, the Single-Use Bioreactor Market is likely to see accelerated growth driven by compliance and safety assurances.

Cost Efficiency and Reduced Time-to-Market

Cost efficiency remains a pivotal driver in the Single-Use Bioreactor Market. The adoption of single-use systems significantly reduces capital investment and operational costs associated with cleaning and sterilization of traditional bioreactors. This reduction in costs is particularly appealing to small and medium-sized enterprises, which may lack the resources for extensive infrastructure. Furthermore, single-use bioreactors facilitate faster production cycles, thereby decreasing time-to-market for new therapeutics. Industry reports suggest that companies utilizing single-use technologies can reduce production timelines by up to 30%, enhancing their competitive edge in a rapidly evolving market.

Technological Advancements in Bioprocessing

Technological advancements play a critical role in shaping the Single-Use Bioreactor Market. Innovations in bioprocessing technologies, such as improved sensor integration and automation, enhance the functionality and efficiency of single-use systems. These advancements allow for real-time monitoring and control of bioprocess parameters, leading to optimized production outcomes. The integration of smart technologies is expected to further streamline operations, reduce human error, and improve product consistency. As these technologies continue to evolve, they are likely to attract more manufacturers to the Single-Use Bioreactor Market, fostering a competitive landscape that prioritizes efficiency and quality.

Focus on Sustainability and Environmental Impact

Sustainability is becoming increasingly important within the Single-Use Bioreactor Market. The shift towards environmentally friendly practices is prompting manufacturers to consider the lifecycle impact of their production processes. Single-use bioreactors, which minimize the need for extensive cleaning and sterilization, contribute to reduced water and energy consumption. Additionally, the materials used in single-use systems are often designed for recyclability or safe disposal, aligning with global sustainability goals. As companies strive to enhance their environmental footprint, the Single-Use Bioreactor Market is likely to see a growing emphasis on sustainable practices, which could influence purchasing decisions and market dynamics.