Technological Innovations

Technological advancements play a pivotal role in shaping the Shelling Machine Market. Innovations such as automation, artificial intelligence, and machine learning are increasingly integrated into shelling machines, enhancing their efficiency and precision. These technologies enable manufacturers to optimize production processes, reduce waste, and improve product quality. For instance, the introduction of smart shelling machines equipped with sensors allows for real-time monitoring and adjustments, ensuring consistent output. As a result, the Shelling Machine Market is witnessing a shift towards more sophisticated machinery that not only meets current demands but also anticipates future market needs.

Growing Export Opportunities

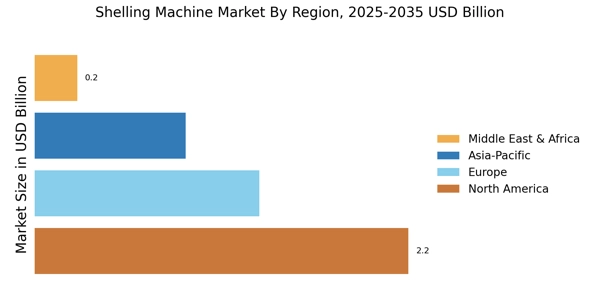

The Shelling Machine Market is poised to benefit from the growing export opportunities in various regions. As countries seek to enhance their agricultural exports, there is an increasing need for efficient processing equipment, including shelling machines. This trend is particularly evident in regions with abundant agricultural resources, where governments are promoting initiatives to boost exports. Reports suggest that the agricultural export market is expected to grow by 7% over the next few years, creating a favorable environment for the Shelling Machine Market. Manufacturers are likely to capitalize on this trend by developing machines tailored to meet the specific needs of international markets.

Expansion of Agricultural Sector

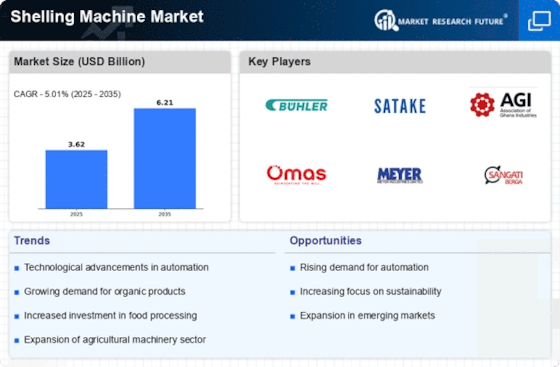

The Shelling Machine Market is significantly influenced by the expansion of the agricultural sector. As farming practices evolve and the global population continues to grow, there is an increasing emphasis on maximizing crop yields and minimizing post-harvest losses. This has led to a heightened demand for efficient shelling machines that can process various agricultural products. Reports indicate that the agricultural machinery market is expected to grow at a rate of 4% annually, which directly correlates with the need for advanced shelling solutions. Consequently, the Shelling Machine Market stands to gain from this agricultural growth, as farmers and processors seek reliable equipment to enhance productivity.

Focus on Food Safety and Quality

Food safety and quality assurance are becoming paramount in the Shelling Machine Market. With increasing regulations and consumer awareness regarding food safety, manufacturers are compelled to invest in shelling machines that adhere to stringent quality standards. This focus on safety not only ensures compliance with regulations but also enhances brand reputation and consumer trust. The market for food safety equipment is projected to grow at a rate of 6% annually, indicating a robust demand for machinery that can guarantee the integrity of shelled products. As such, the Shelling Machine Market is likely to see a rise in demand for machines that incorporate safety features and quality control mechanisms.

Rising Demand for Processed Food

The Shelling Machine Market experiences a notable increase in demand for processed food products. As consumer preferences shift towards convenience and ready-to-eat meals, manufacturers are compelled to enhance their production capabilities. This trend is reflected in the growing need for efficient shelling machines that can process nuts, seeds, and legumes at a higher volume. According to industry reports, the processed food sector is projected to grow at a compound annual growth rate of approximately 5.5% over the next five years. Consequently, the Shelling Machine Market is likely to benefit from this surge, as processors seek advanced machinery to meet the escalating demand for high-quality, shelled products.