Growth in Aerospace Applications

The Screw Machine Market is witnessing significant growth due to its expanding applications in the aerospace sector. The aerospace industry demands precision-engineered components that meet stringent safety and performance standards. In 2025, it is estimated that the aerospace sector will represent around 15% of the overall screw machine market. This growth is fueled by increasing air travel and the need for lightweight, high-strength materials in aircraft manufacturing. Screw machines play a crucial role in producing parts such as fasteners, brackets, and fittings, which are essential for aircraft assembly. As the aerospace industry continues to innovate, the demand for advanced screw machines capable of handling complex designs is likely to rise, further propelling market growth.

Increasing Focus on Customization

Customization is becoming a pivotal factor in the Screw Machine Market, as businesses strive to meet the unique needs of their clients. The demand for tailored solutions is on the rise, with an estimated 20% of screw machine sales in 2025 attributed to customized products. This trend is particularly evident in sectors such as medical devices and electronics, where specific requirements dictate the design and functionality of components. Manufacturers are investing in flexible screw machines that can accommodate various specifications without compromising quality. This shift towards customization not only enhances customer satisfaction but also fosters innovation within the industry, as companies explore new designs and materials to meet evolving market demands.

Rising Demand in Automotive Sector

The Screw Machine Market is experiencing a notable surge in demand, particularly from the automotive sector. As vehicle production ramps up, manufacturers increasingly rely on screw machines for precision components. In 2025, the automotive industry is projected to account for approximately 30% of the total demand for screw machines. This trend is driven by the need for high-quality, durable parts that can withstand rigorous performance standards. Furthermore, the shift towards electric vehicles is likely to create additional opportunities for screw machine manufacturers, as these vehicles require specialized components. The integration of advanced technologies in automotive manufacturing further emphasizes the importance of screw machines, which are essential for producing intricate parts with high accuracy.

Sustainability and Eco-Friendly Practices

Sustainability is increasingly influencing the Screw Machine Market, as manufacturers adopt eco-friendly practices to meet regulatory requirements and consumer expectations. In 2025, it is projected that approximately 30% of screw machine manufacturers will implement sustainable production methods. This includes the use of recyclable materials and energy-efficient processes, which not only reduce environmental impact but also lower operational costs. The growing emphasis on sustainability is prompting companies to innovate in their manufacturing techniques, leading to the development of machines that minimize waste and energy consumption. As industries worldwide prioritize sustainability, the demand for screw machines that align with these values is likely to increase, shaping the future of the market.

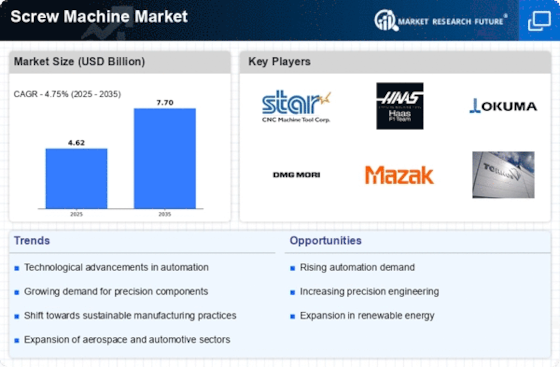

Technological Innovations in Manufacturing

Technological advancements are a key driver in the Screw Machine Market, as manufacturers increasingly adopt automation and smart technologies. The integration of Industry 4.0 principles, such as IoT and AI, is transforming traditional manufacturing processes. In 2025, it is anticipated that around 25% of screw machine manufacturers will implement smart technologies to enhance efficiency and reduce production costs. These innovations enable real-time monitoring and predictive maintenance, which can significantly improve operational efficiency. Additionally, the development of multi-axis screw machines allows for greater flexibility and precision in production, catering to the diverse needs of various industries. As manufacturers seek to optimize their operations, the demand for technologically advanced screw machines is expected to grow.