Growth in Emerging Markets

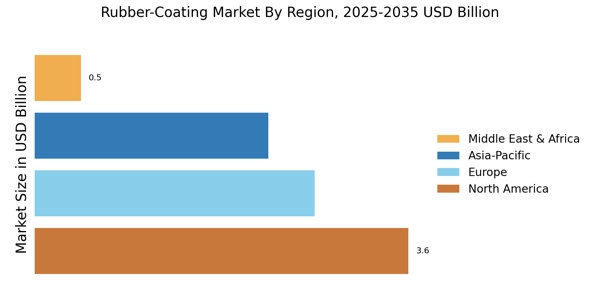

Emerging markets are becoming increasingly significant for the Rubber-Coating Market, as economic development and industrialization drive demand for rubber coatings. Countries in Asia-Pacific and Latin America are witnessing rapid growth in construction, automotive, and manufacturing sectors, which in turn fuels the need for high-quality rubber coatings. The expansion of infrastructure projects and rising disposable incomes in these regions are contributing to increased consumption of rubber-coated products. Market analysts suggest that the growth potential in these emerging economies could surpass that of established markets, presenting lucrative opportunities for manufacturers. As companies seek to capitalize on this trend, the Rubber-Coating Market is likely to experience a shift in focus towards these high-growth regions, fostering innovation and competitive strategies tailored to local needs.

Rising Demand for Eco-Friendly Products

The Rubber-Coating Market is experiencing a notable shift towards eco-friendly products, driven by increasing consumer awareness regarding environmental sustainability. As industries seek to reduce their carbon footprint, the demand for rubber coatings made from natural and recycled materials is on the rise. This trend is reflected in the growing market for bio-based rubber coatings, which is projected to expand significantly in the coming years. Companies are investing in research and development to create innovative, sustainable solutions that meet regulatory standards while appealing to environmentally conscious consumers. The emphasis on sustainability not only enhances brand reputation but also aligns with global initiatives aimed at reducing waste and promoting circular economies. Consequently, the Rubber-Coating Market is likely to witness a surge in demand for products that are both effective and environmentally friendly.

Expanding Applications Across Industries

The versatility of rubber coatings is contributing to their increasing adoption across a multitude of industries, thereby driving growth in the Rubber-Coating Market. Applications range from automotive components to industrial machinery, and even consumer goods. For instance, the automotive sector utilizes rubber coatings for protective and aesthetic purposes, enhancing vehicle longevity and appearance. Similarly, the construction industry employs rubber coatings for waterproofing and surface protection, which is crucial in maintaining structural integrity. According to recent data, the construction segment alone is expected to account for a substantial share of the market, reflecting the broad applicability of rubber coatings. This trend indicates that as industries continue to explore innovative uses for rubber coatings, the Rubber-Coating Market is poised for sustained expansion.

Regulatory Compliance and Safety Standards

The Rubber-Coating Market is increasingly influenced by stringent regulatory compliance and safety standards. Governments and regulatory bodies are implementing guidelines that mandate the use of non-toxic and safe materials in various applications, particularly in sectors such as food packaging and healthcare. This regulatory landscape is compelling manufacturers to innovate and adapt their product offerings to meet these requirements. As a result, there is a growing emphasis on developing rubber coatings that are free from harmful chemicals and that comply with international safety standards. This shift not only ensures consumer safety but also enhances market competitiveness. Companies that prioritize compliance are likely to gain a competitive edge in the Rubber-Coating Market, as they can cater to a broader range of applications while adhering to necessary regulations.

Technological Innovations in Coating Processes

Technological advancements are playing a pivotal role in shaping the Rubber-Coating Market. Innovations in coating processes, such as the development of advanced application techniques and improved curing methods, are enhancing the performance and durability of rubber coatings. These technologies enable manufacturers to produce coatings that exhibit superior adhesion, flexibility, and resistance to wear and tear. Furthermore, the integration of automation and smart technologies in production lines is streamlining operations, reducing costs, and increasing efficiency. As a result, companies are better positioned to meet the diverse needs of various industries, including automotive, construction, and electronics. The ongoing evolution of coating technologies suggests that the Rubber-Coating Market will continue to grow, driven by the demand for high-performance and cost-effective solutions.