Growing Focus on Sustainability

The growing focus on sustainability is significantly influencing the Rail Wheel Market. As environmental concerns become more pronounced, rail operators are increasingly seeking eco-friendly solutions. This trend is prompting manufacturers to develop rail wheels that are not only durable but also produced through sustainable practices. For instance, the use of recycled materials in wheel production is gaining popularity, aligning with global sustainability goals. Additionally, rail systems are being designed to minimize energy consumption, which further drives the demand for innovative rail wheel technologies. Recent studies indicate that sustainable rail solutions could reduce greenhouse gas emissions by up to 30% in the transportation sector. Consequently, the Rail Wheel Market is likely to evolve, with a stronger emphasis on environmentally responsible manufacturing processes.

Expansion of High-Speed Rail Networks

The expansion of high-speed rail networks is emerging as a crucial driver for the Rail Wheel Market. Countries are increasingly investing in high-speed rail systems to enhance connectivity and reduce travel times. This trend is particularly evident in regions where rail travel is seen as a viable alternative to air travel. High-speed trains require specialized rail wheels designed to withstand higher speeds and stresses, thereby creating a distinct market segment within the Rail Wheel Market. Recent projections suggest that the high-speed rail segment could grow at a rate of 6% annually over the next five years. As more nations embark on high-speed rail projects, the demand for advanced rail wheels is expected to rise, prompting manufacturers to innovate and adapt to these specific requirements.

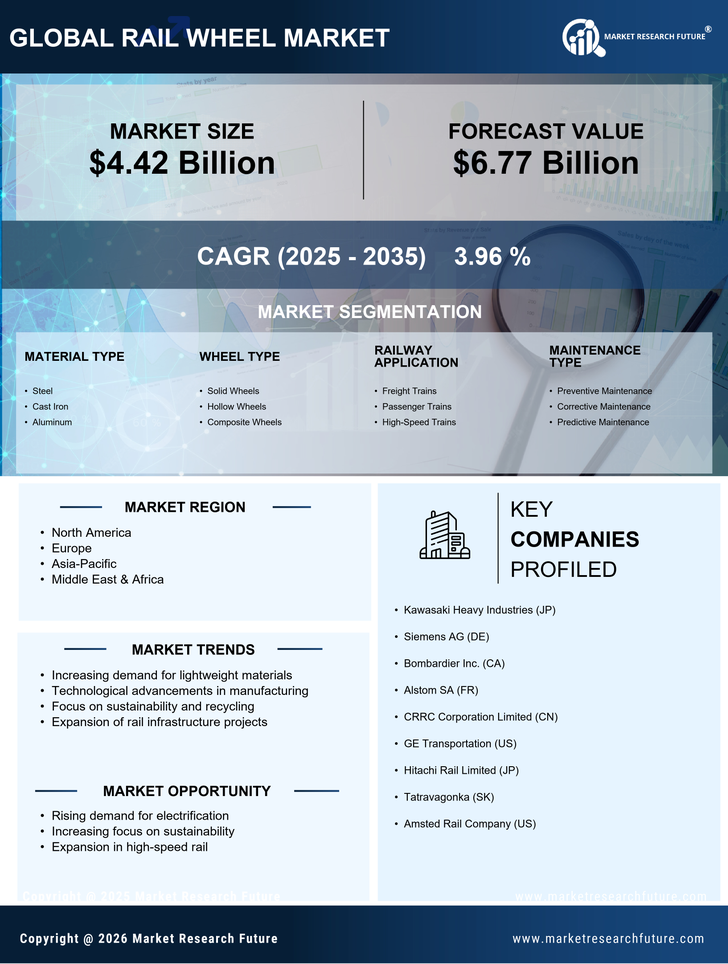

Increasing Demand for Rail Transportation

The Rail Wheel Market is experiencing a notable surge in demand for rail transportation, driven by the need for efficient and sustainable logistics solutions. As urbanization accelerates, cities are increasingly investing in rail infrastructure to alleviate traffic congestion and reduce carbon emissions. According to recent data, rail transport is projected to grow at a compound annual growth rate of approximately 4.5% over the next five years. This growth is likely to stimulate the Rail Wheel Market, as more rail systems require high-quality wheels to ensure safety and performance. Furthermore, the shift towards electrification in rail systems necessitates advanced rail wheel technologies, which could further enhance market prospects. Consequently, manufacturers are focusing on innovation to meet the evolving demands of the rail sector.

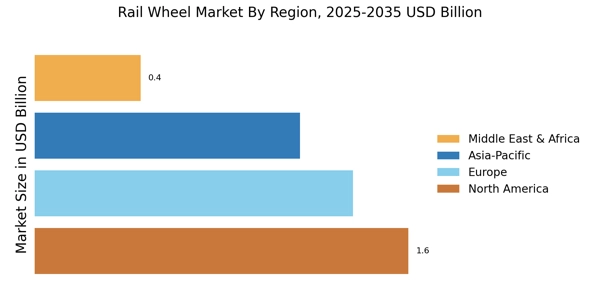

Government Investments in Rail Infrastructure

Government investments in rail infrastructure are a pivotal driver for the Rail Wheel Market. Many countries are prioritizing rail projects as part of their economic recovery strategies, recognizing the long-term benefits of enhanced rail networks. For instance, recent reports indicate that several nations are allocating substantial budgets to upgrade existing rail systems and develop new lines. This influx of capital is expected to create a robust demand for rail wheels, as new and refurbished trains require reliable and durable components. Additionally, public-private partnerships are emerging as a viable model for financing rail projects, further bolstering the Rail Wheel Market. As these investments materialize, manufacturers are likely to see increased orders, thereby stimulating production and innovation within the sector.

Technological Innovations in Rail Wheel Manufacturing

Technological innovations are reshaping the Rail Wheel Market, as manufacturers adopt advanced materials and production techniques to enhance wheel performance. The introduction of lightweight materials, such as high-strength steel and composite materials, is expected to improve fuel efficiency and reduce wear and tear on rail systems. Moreover, the integration of smart technologies, such as sensors for real-time monitoring, is gaining traction. These innovations not only enhance safety but also optimize maintenance schedules, thereby reducing operational costs for rail operators. Recent advancements suggest that the adoption of these technologies could lead to a 15% reduction in maintenance costs over the next decade. As a result, the Rail Wheel Market is likely to witness increased competition among manufacturers striving to offer cutting-edge solutions.