Regulatory Compliance

Regulatory compliance is a critical driver for the Radiation Cured Coating Market. Stricter environmental regulations regarding VOC emissions and hazardous materials are prompting manufacturers to transition towards radiation cured coatings. These coatings not only comply with regulations but also offer enhanced performance characteristics. In 2025, the market is likely to see increased adoption as companies strive to meet compliance standards while maintaining product quality. This trend is particularly evident in industries such as construction and automotive, where adherence to regulations is paramount. Consequently, the demand for radiation cured coatings is expected to rise, reinforcing their significance in the market.

Technological Innovations

Technological innovations play a pivotal role in shaping the Radiation Cured Coating Market. Advancements in UV and electron beam curing technologies have led to improved efficiency and performance of coatings. These innovations enable faster curing times and enhanced durability, making radiation cured coatings more appealing to manufacturers. In 2025, the market is anticipated to witness a surge in demand for high-performance coatings, particularly in the automotive and electronics sectors. The integration of smart technologies, such as sensors and automation, further enhances the application of radiation cured coatings, indicating a robust growth trajectory for the industry.

Sustainability Initiatives

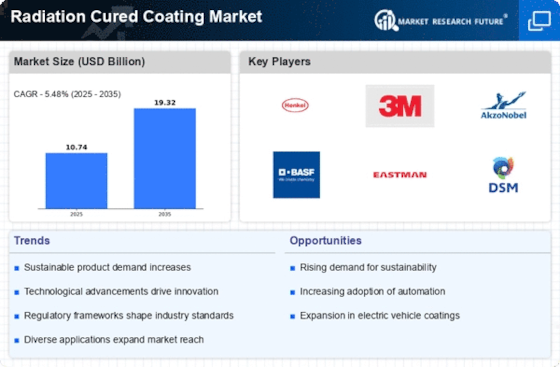

The Radiation Cured Coating Market is increasingly influenced by sustainability initiatives. As environmental concerns gain prominence, manufacturers are compelled to adopt eco-friendly practices. Radiation cured coatings, known for their low volatile organic compound (VOC) emissions, align with these sustainability goals. The market is projected to grow as industries seek to minimize their environmental footprint. In 2025, the demand for sustainable coatings is expected to rise, with a notable increase in applications across automotive, furniture, and packaging sectors. This shift towards sustainability not only enhances brand reputation but also meets regulatory requirements, thereby driving growth in the Radiation Cured Coating Market.

Diverse End-Use Applications

The Radiation Cured Coating Market benefits from a wide array of end-use applications. Industries such as automotive, electronics, and packaging are increasingly adopting radiation cured coatings due to their superior properties. For instance, in the automotive sector, these coatings provide excellent scratch resistance and durability, which are essential for vehicle longevity. The packaging industry also leverages these coatings for their quick curing capabilities, enhancing production efficiency. As of 2025, the market is expected to expand significantly, driven by the growing demand for high-quality coatings across various sectors, thereby solidifying the position of radiation cured coatings in the market.

Economic Growth and Industrial Expansion

Economic growth and industrial expansion are significant factors influencing the Radiation Cured Coating Market. As economies recover and expand, there is a corresponding increase in manufacturing activities, which drives the demand for high-performance coatings. In 2025, the market is projected to benefit from the resurgence of various industries, including automotive, aerospace, and consumer goods. This growth is likely to be fueled by rising disposable incomes and consumer preferences for durable and aesthetically pleasing products. As industries seek to enhance their offerings, the adoption of radiation cured coatings is expected to rise, indicating a positive outlook for the market.