Production Information Management Size

Market Size Snapshot

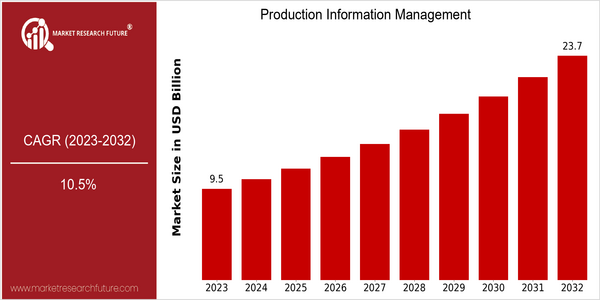

| Year | Value |

|---|---|

| 2023 | USD 9.52 Billion |

| 2032 | USD 23.72 Billion |

| CAGR (2024-2032) | 10.5 % |

Note – Market size depicts the revenue generated over the financial year

Production Information Management Market will reach USD 23.72 billion by 2032, growing at a CAGR of 10.5% between 2023 and 2032. This growth is mainly due to the increasing importance of the production information management system in various industries. The need for operational efficiency, data accuracy and real-time decision-making is growing. The demand for integrated solutions that improve data visibility and optimize production processes is also increasing. Industry 4.0 is also driving this growth. Industry 4.0 emphasizes automation and data exchange in manufacturing technology. It also promotes the use of cloud-based solutions and big data analysis to optimize production efficiency and reduce production costs. The major players in this market, such as Siemens, SAP, and Oracle, are actively investing in the development of new products and establishing strategic cooperation with other companies. The integration of artificial intelligence and the Internet of Things into the production information management system is an example of this trend. The demand for intelligent and flexible solutions is expected to drive the market.

Regional Market Size

Regional Deep Dive

Production information management is a market that is growing in different regions of the world. It is a market that is driven by the growing need for data management and real-time analysis of production processes. In North America, the market is characterized by advanced technological implementation and a strong presence of key players, while Europe focuses on regulatory compliance and sustainability. Asia-Pacific is experiencing rapid industrialization and digitalization, which is expected to lead to a growing demand for production information solutions. Middle East and Africa are gradually embracing these solutions, influenced by economic diversification. Production information management is used to improve the operational efficiency of manufacturing industries in Latin America.

Europe

- The European Union's Green Deal is driving manufacturers to adopt sustainable practices, leading to a surge in demand for production information management systems that can track and optimize resource usage.

- Companies such as SAP and Dassault Systèmes are developing advanced analytics tools that integrate with production information management systems, enhancing decision-making capabilities for manufacturers.

Asia Pacific

- China's 'Made in China 2025' initiative is pushing manufacturers to adopt advanced production information management systems to improve efficiency and competitiveness on a global scale.

- The rise of smart factories in Japan, supported by companies like Fanuc and Mitsubishi Electric, is leading to increased integration of IoT and AI in production information management, enhancing real-time data processing.

Latin America

- Brazil's manufacturing sector is increasingly adopting production information management systems to improve productivity and reduce waste, driven by government incentives for digital transformation.

- Organizations like Embraer are leveraging production information management to streamline operations and enhance supply chain visibility, reflecting a broader trend in the region towards modernization.

North America

- The rise of Industry 4.0 has led to increased investments in smart manufacturing technologies, with companies like Siemens and Rockwell Automation spearheading innovations in production information management systems.

- Changes in the regulations, especially in the field of privacy and security, have led companies to invest in more powerful production information management systems to ensure compliance, as shown by the recent implementation of the Californian data protection act.

Middle East And Africa

- The UAE's Vision 2021 is promoting the adoption of advanced manufacturing technologies, including production information management systems, to diversify the economy away from oil dependency.

- Local companies, such as Al-Futtaim Technologies, are partnering with global firms to implement production information management solutions that enhance operational efficiency in various sectors.

Did You Know?

“Approximately 70% of manufacturers in North America are expected to invest in production information management solutions within the next five years to enhance operational efficiency.” — Manufacturing Institute

Segmental Market Size

The PIM market segment plays a key role in enhancing the efficiency and accuracy of data management across a wide range of industries, including manufacturing and retail. The market is growing, driven by the increasing need for real-time access to data and integration across supply chains. E-commerce, which demands accurate product information, and regulatory compliance, which is especially critical in the pharmaceutical and food industries, are two of the major growth drivers for PIMs. The PIM market is in a mature stage of deployment, with companies like SAP and Oracle leading the way in offering robust PIM solutions. North America and Europe are the leading regions in the use of PIMs for product lifecycle management. The most important PIM applications are in the areas of inventory management, product cataloguing, and data governance. The PIM market is driven by industries such as fashion and consumer electronics. PIMs are also being pushed by trends such as digital transformation and sustainable business practices. PIMs are also being shaped by new technology trends such as cloud computing and artificial intelligence.

Future Outlook

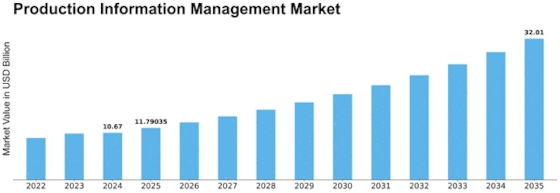

The PIM market will grow from $9.5 billion to $23.7 billion by 2032, a CAGR of 10.5%. This growth is driven by the need for companies to optimize their production processes and improve data accuracy in their supply chains. By 2032, the penetration of advanced PIMs in various industries is expected to reach over 60%, especially in the manufacturing, retail, and logistics industries. Artificial intelligence and machine learning are the main technological drivers of the PIM. PIMs will be able to process more data, making it possible to make more accurate predictions and optimize production processes. Also, the development of Industry 4.0 and the Internet of Things will further promote the real-time sharing of data and collaboration between all parties, thereby increasing the efficiency of supply chains. The trend of sustainable development and the trend of compliance will also shape the PIM. Companies will gradually conform to the requirements of consumers and the environment, and will gradually align their production practices with these requirements. In the future, the PIM market will have a bright future, and it will have a large space for innovation and development.

Leave a Comment