Growth in the Electronics Sector

The Precision Machine For Polymer Market is significantly influenced by the burgeoning electronics sector, which increasingly relies on advanced polymer materials for components such as casings, insulators, and circuit boards. The market for electronic devices is projected to grow at a compound annual growth rate of approximately 8% through 2027, thereby amplifying the need for precision machining capabilities. As electronic devices become more compact and complex, the demand for precision machines that can handle intricate polymer designs is likely to rise. This growth not only enhances the market for precision machines but also encourages innovation in polymer formulations, leading to improved performance and durability of electronic products.

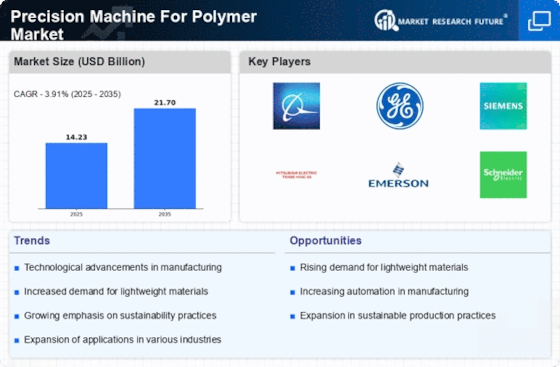

Rising Demand for Lightweight Materials

The Precision Machine For Polymer Market is experiencing a notable increase in demand for lightweight materials, particularly in sectors such as automotive and aerospace. Manufacturers are increasingly adopting polymers due to their favorable strength-to-weight ratios, which enhance fuel efficiency and reduce emissions. This trend is supported by data indicating that the automotive sector alone is projected to utilize polymers in over 50% of its components by 2026. As a result, precision machines designed for polymer processing are becoming essential for manufacturers aiming to meet these evolving material requirements. The ability to produce intricate designs with high precision further drives the adoption of these machines, as companies seek to innovate while maintaining compliance with stringent industry standards.

Regulatory Compliance and Quality Standards

The Precision Machine For Polymer Market is increasingly shaped by stringent regulatory compliance and quality standards across various sectors, including healthcare and automotive. Manufacturers are required to adhere to specific guidelines that ensure product safety and performance, which in turn drives the demand for precision machines capable of producing high-quality polymer components. For instance, the medical device industry mandates rigorous testing and certification processes, leading to a heightened need for precision machining technologies that can meet these standards. As regulations continue to evolve, companies are likely to invest in advanced precision machines to ensure compliance, thereby fostering growth within the market.

Emergence of Smart Manufacturing Technologies

The Precision Machine For Polymer Market is witnessing a transformative shift due to the emergence of smart manufacturing technologies. These innovations, including the Internet of Things (IoT) and artificial intelligence, are revolutionizing the way precision machines operate. By integrating smart technologies, manufacturers can enhance operational efficiency, reduce waste, and improve product quality. Data suggests that the adoption of smart manufacturing solutions could lead to a 20% increase in productivity within the polymer processing sector by 2026. This trend not only drives the demand for advanced precision machines but also encourages manufacturers to adopt more sustainable practices, aligning with broader industry goals of reducing environmental impact.

Increased Investment in Research and Development

Investment in research and development within the Precision Machine For Polymer Market is on the rise, as companies strive to enhance their manufacturing processes and product offerings. This trend is evidenced by a reported increase in R&D spending by approximately 15% in the polymer processing sector over the past two years. Such investments are aimed at developing advanced precision machines that can accommodate new polymer materials and complex geometries. Furthermore, the focus on automation and smart manufacturing technologies is likely to drive the evolution of precision machines, making them more efficient and capable of producing high-quality products. This emphasis on innovation is expected to yield significant competitive advantages for companies that effectively leverage these advancements.