Growth in Aerospace Applications

The Precision Grinding Wheels Market is significantly influenced by the aerospace sector, which demands high precision and reliability in its components. The aerospace industry has been expanding, with projections indicating a compound annual growth rate of around 5% through 2025. This growth is likely to drive the need for precision grinding wheels, as they are essential for manufacturing critical components such as turbine blades and landing gear. The stringent quality standards and safety regulations in aerospace manufacturing further emphasize the necessity for high-performance grinding wheels. As the industry continues to evolve, the Precision Grinding Wheels Market is expected to benefit from increased investments in aerospace technology and production capabilities.

Rising Demand in Automotive Sector

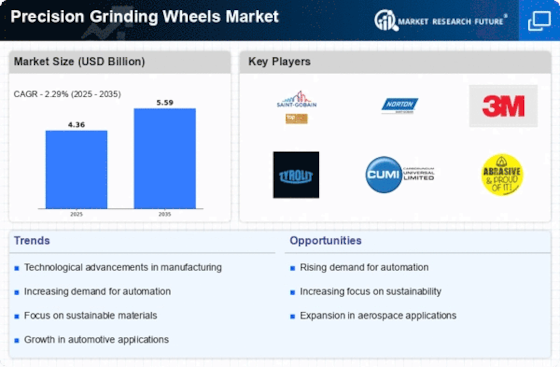

The Precision Grinding Wheels Market is experiencing a notable surge in demand, particularly driven by the automotive sector. As manufacturers strive for enhanced efficiency and precision in vehicle production, the need for high-quality grinding wheels has escalated. In 2025, the automotive industry is projected to account for a substantial share of the market, with estimates suggesting it could reach approximately 30% of total sales. This trend is likely to continue as electric vehicles and advanced manufacturing techniques gain traction, necessitating the use of precision grinding wheels for components such as gears and bearings. Consequently, the Precision Grinding Wheels Market is poised for growth, as automotive manufacturers increasingly prioritize quality and performance in their production processes.

Expansion of Industrial Manufacturing

The Precision Grinding Wheels Market is poised for growth due to the expansion of industrial manufacturing activities. As economies recover and industrial production ramps up, the demand for precision grinding wheels is likely to increase. Industries such as metalworking, machinery, and tool manufacturing are expected to drive this demand, with projections indicating a potential increase in market size by 10% by the end of 2025. The need for precision in machining processes is paramount, and grinding wheels are essential for achieving the desired surface finishes and tolerances. As industrial manufacturing continues to evolve, the Precision Grinding Wheels Market is well-positioned to capitalize on these trends.

Increasing Focus on Manufacturing Efficiency

The Precision Grinding Wheels Market is benefiting from a growing emphasis on manufacturing efficiency across various sectors. Companies are increasingly adopting lean manufacturing principles and automation to streamline their production processes. This shift is likely to drive the demand for precision grinding wheels, as they play a crucial role in achieving high levels of accuracy and consistency in manufacturing. In 2025, it is anticipated that the market will see a rise in the adoption of automated grinding systems, which require specialized grinding wheels to maintain optimal performance. As manufacturers strive to enhance their operational efficiency, the Precision Grinding Wheels Market is expected to experience robust growth.

Technological Innovations in Grinding Processes

Technological advancements are reshaping the Precision Grinding Wheels Market, as innovations in grinding processes enhance efficiency and effectiveness. The introduction of advanced materials and coatings for grinding wheels is enabling manufacturers to achieve superior performance and longer tool life. For instance, the adoption of diamond and CBN (cubic boron nitride) wheels is becoming more prevalent, as they offer exceptional hardness and thermal stability. These innovations are likely to lead to increased productivity and reduced operational costs for manufacturers. As companies seek to optimize their grinding operations, the Precision Grinding Wheels Market is expected to witness a shift towards more sophisticated grinding technologies, thereby driving market growth.