Increased Industrial Automation

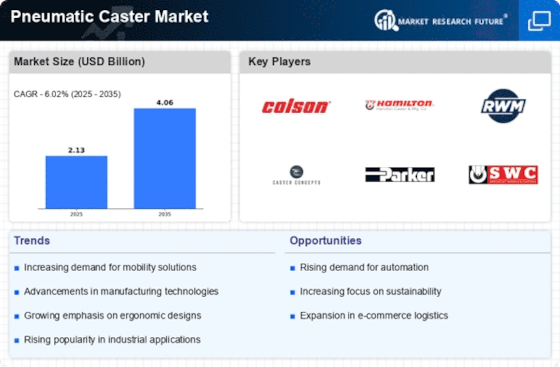

The Pneumatic Caster Market is experiencing a notable surge due to the increasing adoption of industrial automation across various sectors. As manufacturers seek to enhance operational efficiency, the demand for equipment that facilitates smooth movement of goods has escalated. Pneumatic casters, known for their ability to absorb shock and reduce noise, are becoming essential in automated environments. According to recent data, the industrial automation sector is projected to grow at a compound annual growth rate of approximately 9% over the next five years. This growth is likely to drive the demand for pneumatic casters, as they are integral to the functionality of automated systems, thereby reinforcing their position in the market.

Expansion of E-commerce Logistics

The Pneumatic Caster Market is significantly impacted by the rapid expansion of e-commerce logistics. As online shopping continues to gain traction, the need for efficient warehousing and distribution solutions has become critical. Pneumatic casters are increasingly utilized in logistics operations due to their ability to facilitate the smooth movement of goods within warehouses. The e-commerce sector is projected to grow at a rate of 14% annually, which is likely to bolster the demand for pneumatic casters as essential components in logistics equipment. This growth reflects the broader trend of digital transformation in retail, emphasizing the importance of pneumatic casters in supporting efficient supply chain operations.

Growth in Material Handling Equipment

The Pneumatic Caster Market is significantly influenced by the expansion of the material handling equipment sector. As industries increasingly prioritize efficient logistics and supply chain management, the need for reliable and durable casters has intensified. Pneumatic casters are particularly favored for their ability to navigate uneven surfaces and provide a cushioned ride, which is crucial in warehouses and distribution centers. Market analysis indicates that the material handling equipment market is expected to reach a valuation of over 200 billion by 2026, suggesting a robust demand for pneumatic casters as integral components of this equipment. This trend underscores the importance of pneumatic casters in enhancing operational efficiency and safety in material handling.

Rising Demand for Ergonomic Solutions

The Pneumatic Caster Market is witnessing a shift towards ergonomic solutions as businesses increasingly recognize the importance of employee well-being. Pneumatic casters contribute to creating a safer and more comfortable working environment by minimizing physical strain during the movement of heavy loads. This trend is particularly evident in sectors such as healthcare and retail, where the need for mobility solutions that prioritize user comfort is paramount. As organizations invest in ergonomic equipment, the demand for pneumatic casters is likely to rise. Research indicates that ergonomic interventions can lead to a 25% reduction in workplace injuries, further driving the adoption of pneumatic casters in various industries.

Technological Innovations in Caster Design

The Pneumatic Caster Market is benefiting from ongoing technological innovations in caster design and materials. Advances in manufacturing techniques and materials science have led to the development of lighter, more durable pneumatic casters that offer enhanced performance. These innovations not only improve the load-bearing capacity of casters but also contribute to better maneuverability and reduced maintenance costs. As industries seek to optimize their operations, the demand for technologically advanced pneumatic casters is likely to increase. Market forecasts suggest that the introduction of smart casters, equipped with sensors for tracking and monitoring, could further revolutionize the industry, making pneumatic casters an even more attractive option for various applications.