Rising Demand for Biopharmaceuticals

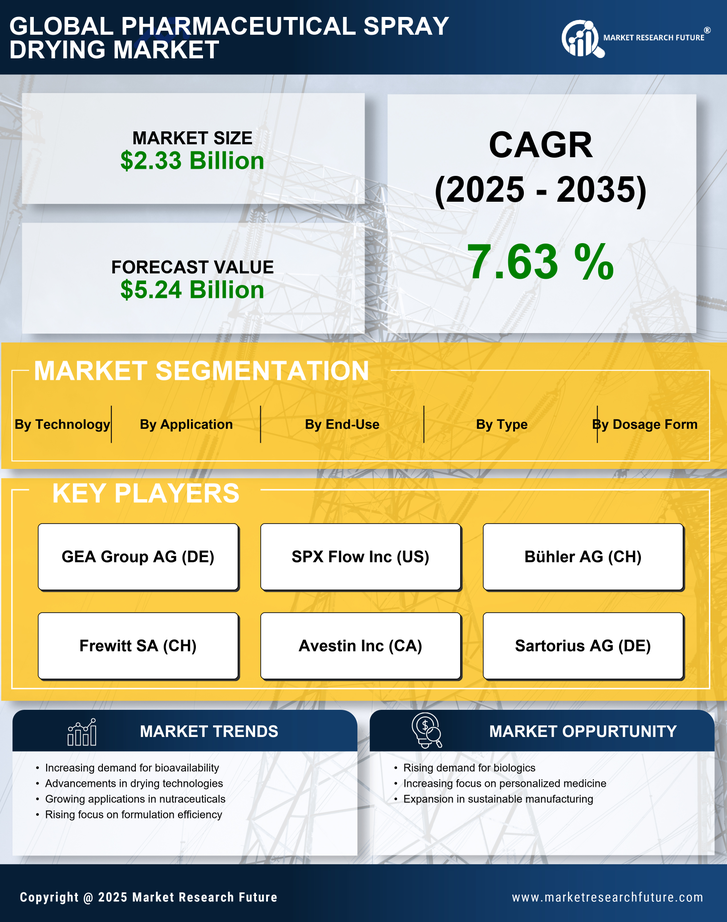

The increasing prevalence of chronic diseases and the growing focus on biopharmaceuticals are driving the Pharmaceutical Spray Drying Market. Biopharmaceuticals, which include monoclonal antibodies and vaccines, require precise formulation techniques to ensure stability and efficacy. Spray drying offers a method to produce dry powders that maintain the integrity of sensitive biological compounds. According to recent data, the biopharmaceutical sector is projected to grow at a compound annual growth rate of over 8% in the coming years, further propelling the demand for advanced drying technologies. This trend indicates a robust market potential for spray drying solutions tailored to biopharmaceutical applications.

Growing Focus on Drug Delivery Systems

The Pharmaceutical Spray Drying Market is experiencing growth due to the increasing emphasis on innovative drug delivery systems. Spray drying is utilized to create nanoparticles and microparticles that enhance the bioavailability of poorly soluble drugs. This method allows for the development of formulations that can improve patient compliance and therapeutic outcomes. With the rise of personalized medicine, the need for tailored drug delivery solutions is becoming more pronounced. Market analysis suggests that the drug delivery systems segment is expected to grow at a rate of 7% annually, indicating a strong correlation with the demand for spray drying technologies.

Advancements in Spray Drying Technology

Technological innovations in spray drying processes are significantly influencing the Pharmaceutical Spray Drying Market. Enhanced equipment designs, such as improved nozzle technology and better control systems, allow for more efficient and consistent drying of pharmaceutical products. These advancements not only improve product quality but also reduce operational costs. The market for spray drying equipment is expected to witness a growth rate of approximately 6% annually, driven by these technological improvements. As manufacturers seek to optimize production processes, the demand for state-of-the-art spray drying solutions is likely to increase, thereby expanding the market.

Expansion of Pharmaceutical R&D Activities

The Pharmaceutical Spray Drying Market is bolstered by the expansion of research and development activities within the pharmaceutical sector. Increased investment in R&D is leading to the discovery of new drugs and formulations, many of which require advanced drying techniques for optimal stability and delivery. The pharmaceutical R&D expenditure is projected to rise significantly, with many companies allocating substantial budgets to explore innovative drug formulations. This trend suggests a growing need for spray drying technologies that can accommodate the diverse requirements of new pharmaceutical products, thereby driving market growth.

Regulatory Support for Advanced Manufacturing

Regulatory bodies are increasingly supporting advanced manufacturing techniques, which is beneficial for the Pharmaceutical Spray Drying Market. Initiatives aimed at promoting innovative manufacturing processes are being implemented to ensure the quality and safety of pharmaceutical products. This regulatory environment encourages companies to adopt spray drying technologies, which are recognized for their efficiency and ability to produce high-quality formulations. As regulations evolve to favor modern manufacturing practices, the market for spray drying is likely to expand, with more companies investing in these technologies to comply with stringent quality standards.