Technological Innovations

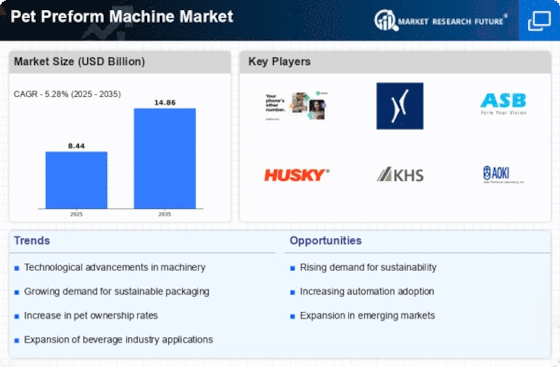

Technological advancements play a crucial role in shaping the Pet Preform Machine Market. Innovations such as automation, artificial intelligence, and enhanced energy efficiency are transforming production processes. For instance, the introduction of high-speed machines capable of producing thousands of preforms per hour is revolutionizing manufacturing capabilities. In 2025, it is estimated that the market for advanced pet preform machines will grow by approximately 15%, driven by these technological improvements. Furthermore, the integration of smart technologies allows for real-time monitoring and predictive maintenance, reducing downtime and operational costs. As manufacturers seek to optimize their production lines, the demand for technologically advanced pet preform machines is likely to increase, further propelling the market.

Sustainability Initiatives

The growing emphasis on sustainability is significantly influencing the Pet Preform Machine Market. With increasing awareness regarding environmental issues, companies are actively seeking eco-friendly packaging solutions. The shift towards recyclable materials and sustainable production practices is driving the demand for PET preform machines that can produce lightweight and recyclable preforms. In 2025, the market for sustainable packaging is projected to grow by 10%, reflecting a broader trend towards environmental responsibility. Manufacturers are likely to invest in machines that not only meet production needs but also align with sustainability goals. This focus on eco-friendly practices is expected to enhance the Pet Preform Machine Market as businesses adapt to changing consumer preferences.

Rising Demand for PET Bottles

The increasing demand for PET bottles across various sectors, including beverages, food, and personal care, is a primary driver for the Pet Preform Machine Market. As consumers become more health-conscious, the preference for bottled water and other beverages continues to rise. In 2025, the consumption of PET bottles is projected to reach approximately 20 million tons, indicating a robust growth trajectory. This surge in demand necessitates efficient production processes, thereby propelling the need for advanced pet preform machines. Manufacturers are likely to invest in innovative technologies to enhance production efficiency and meet the growing market requirements. Consequently, the Pet Preform Machine Market is expected to witness significant expansion as companies strive to capitalize on this increasing demand.

Expansion of Beverage Industry

The expansion of the beverage industry is a significant driver for the Pet Preform Machine Market. As new beverage brands emerge and existing companies expand their product lines, the demand for PET preforms is likely to increase. In 2025, the beverage sector is anticipated to grow by approximately 8%, leading to a corresponding rise in the need for efficient preform production. This growth is fueled by trends such as health and wellness, with consumers increasingly opting for functional beverages. Consequently, manufacturers are expected to invest in advanced pet preform machines to meet the rising production demands. The Pet Preform Machine Market stands to benefit from this expansion as companies seek to enhance their production capabilities.

Emerging Markets and Urbanization

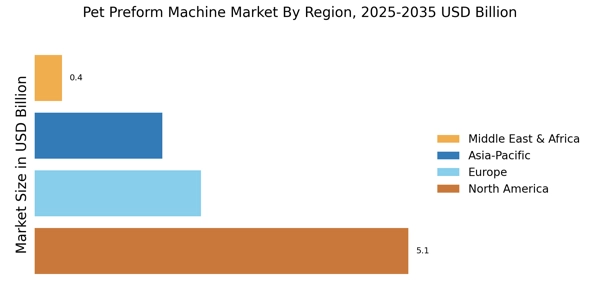

Emerging markets and urbanization are pivotal factors driving the Pet Preform Machine Market. As urban populations grow, the demand for packaged goods, including beverages and food products, is on the rise. In 2025, it is projected that urbanization will contribute to a 12% increase in the demand for PET packaging solutions. This trend is particularly evident in developing regions, where rising disposable incomes and changing lifestyles are leading to increased consumption of packaged products. Manufacturers are likely to focus on these emerging markets, adapting their production strategies to cater to local preferences. The Pet Preform Machine Market is expected to experience growth as companies capitalize on the opportunities presented by urbanization and the expanding middle class.