Focus on Labor Cost Reduction

A pronounced focus on labor cost reduction is emerging as a key driver in the Palletizing Machine Market. Companies are increasingly recognizing the financial benefits of automating palletizing processes to minimize labor expenses. With labor costs rising in many regions, businesses are compelled to seek solutions that enhance productivity while reducing reliance on manual labor. The implementation of palletizing machines can lead to substantial savings, as these systems operate continuously and require minimal human intervention. Recent analyses indicate that companies can achieve a return on investment within two years of adopting automated palletizing solutions. This trend is likely to propel the Palletizing Machine Market forward, as more organizations prioritize automation to remain competitive and improve their bottom line.

Growth of E-commerce and Retail Sectors

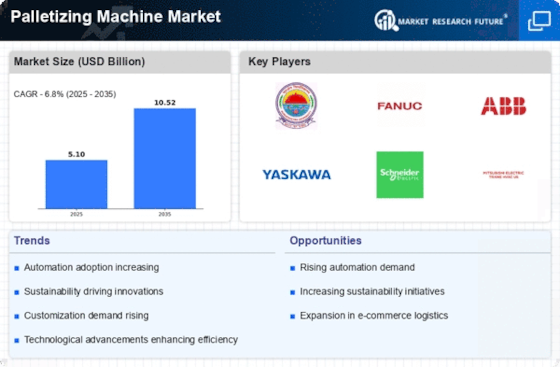

The growth of the e-commerce and retail sectors is significantly influencing the Palletizing Machine Market. As online shopping continues to gain traction, the demand for efficient warehousing and distribution solutions has escalated. E-commerce companies are increasingly investing in automated palletizing systems to manage high volumes of orders and ensure timely deliveries. Data suggests that the e-commerce sector is expected to reach a valuation of over 6 trillion dollars by 2024, which will likely drive the need for advanced palletizing solutions. This trend is prompting manufacturers to develop machines that can handle a variety of packaging types and sizes, thereby enhancing operational efficiency. Consequently, the Palletizing Machine Market is poised for growth as businesses adapt to the evolving landscape of consumer behavior and logistics requirements.

Technological Advancements in Automation

Technological advancements play a pivotal role in shaping the Palletizing Machine Market. Innovations such as artificial intelligence, machine learning, and robotics are transforming traditional palletizing processes into highly automated systems. These advancements enable machines to adapt to various product types and sizes, enhancing flexibility and efficiency. Recent studies indicate that the integration of smart technologies in palletizing systems can lead to a 30% increase in productivity. As manufacturers continue to invest in automation, the Palletizing Machine Market is expected to expand, driven by the need for faster production rates and reduced operational costs. Furthermore, the ongoing development of collaborative robots, or cobots, is likely to enhance the capabilities of palletizing machines, allowing for safer and more efficient operations in diverse environments.

Increased Emphasis on Safety and Ergonomics

The Palletizing Machine Market is witnessing an increased emphasis on safety and ergonomics in the workplace. As companies strive to create safer working environments, the demand for automated palletizing solutions that minimize manual handling is growing. Automated systems reduce the risk of workplace injuries associated with heavy lifting and repetitive motions, thereby enhancing employee safety. Recent statistics indicate that businesses that implement ergonomic solutions can reduce workplace injuries by up to 40%. This focus on safety not only benefits employees but also improves overall operational efficiency. As a result, the Palletizing Machine Market is likely to see a rise in the adoption of machines designed with advanced safety features and ergonomic considerations, aligning with broader trends in workplace health and safety.

Rising Demand for Efficient Logistics Solutions

The Palletizing Machine Market is experiencing a surge in demand for efficient logistics solutions. As businesses strive to optimize their supply chains, the need for automated palletizing systems has become increasingly apparent. According to recent data, the logistics sector is projected to grow at a compound annual growth rate of 7.5% over the next five years. This growth is driven by the need for faster and more reliable delivery systems, which in turn fuels the demand for advanced palletizing machines. These machines not only enhance operational efficiency but also reduce labor costs, making them an attractive investment for companies looking to streamline their operations. Consequently, the Palletizing Machine Market is likely to see significant advancements in technology and increased adoption rates as businesses seek to remain competitive in a rapidly evolving market.