Growing Adoption in Emerging Markets

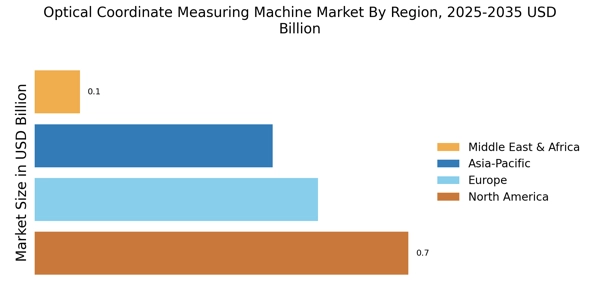

Emerging markets are becoming a focal point for the Optical Coordinate Measuring Machine Market. As industrialization accelerates in regions such as Asia-Pacific and Latin America, the demand for precision measurement tools is on the rise. Companies in these regions are increasingly investing in advanced manufacturing technologies to compete on a global scale. The growing automotive and electronics industries in these markets are particularly driving the demand for optical coordinate measuring machines. Market forecasts indicate that the adoption rate in these emerging economies could significantly contribute to the overall market growth, as businesses seek to enhance their operational capabilities and product quality.

Increased Demand for Quality Control

Quality control remains a pivotal driver in the Optical Coordinate Measuring Machine Market. As industries strive to meet stringent quality standards, the need for precise measurement tools has become paramount. Optical coordinate measuring machines provide the accuracy required to ensure that products meet specifications, thereby reducing waste and enhancing customer satisfaction. The automotive and aerospace sectors, in particular, are witnessing a heightened focus on quality assurance, leading to increased investments in optical coordinate measuring technologies. Market data indicates that the quality control segment is expected to account for a significant share of the overall market, reflecting the critical role these machines play in maintaining high standards.

Shift Towards Automation in Manufacturing

The Optical Coordinate Measuring Machine Market is witnessing a notable shift towards automation in manufacturing processes. As companies seek to enhance productivity and reduce human error, the integration of optical coordinate measuring machines into automated systems is becoming increasingly common. These machines facilitate real-time data collection and analysis, enabling manufacturers to make informed decisions swiftly. The trend towards Industry 4.0, characterized by smart factories and interconnected devices, is further propelling the adoption of optical coordinate measuring machines. Market analysts suggest that this shift could lead to a substantial increase in demand, as manufacturers recognize the benefits of automated quality assurance processes.

Rising Need for Customization in Manufacturing

Customization in manufacturing is becoming a critical driver for the Optical Coordinate Measuring Machine Market. As consumer preferences shift towards personalized products, manufacturers are compelled to adopt flexible production methods that require precise measurement capabilities. Optical coordinate measuring machines offer the versatility needed to accommodate various design specifications and production requirements. This trend is particularly evident in sectors such as consumer electronics and medical devices, where tailored solutions are increasingly in demand. Market Research Future suggest that the ability to provide customized measurement solutions will likely enhance the competitive edge of manufacturers, thereby fueling the growth of the optical coordinate measuring machine market.

Technological Advancements in Measurement Techniques

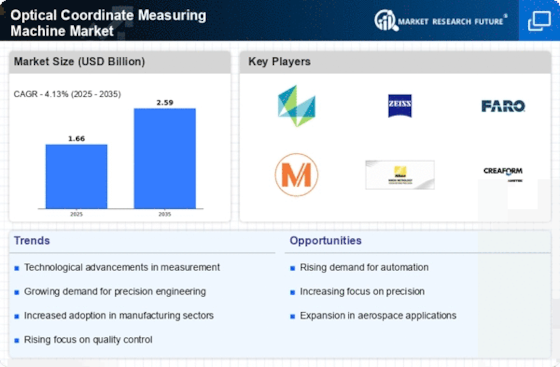

The Optical Coordinate Measuring Machine Market is experiencing a surge in technological advancements that enhance measurement precision and efficiency. Innovations such as laser scanning and advanced imaging techniques are being integrated into optical coordinate measuring machines, allowing for more accurate data collection. These advancements are not only improving the speed of measurements but also expanding the range of applications across various sectors, including aerospace, automotive, and manufacturing. As industries increasingly prioritize precision engineering, the demand for sophisticated optical coordinate measuring machines is likely to rise. According to recent data, the market is projected to grow at a compound annual growth rate of approximately 7% over the next five years, driven by these technological improvements.