Market Growth Projections

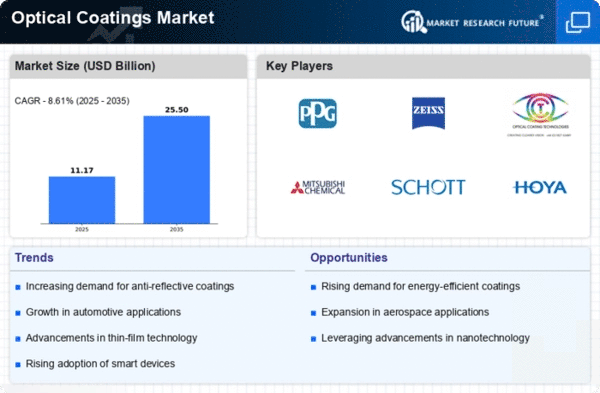

The Global Optical Coatings Market Industry is poised for substantial growth, with projections indicating a market value of 14.1 USD Billion in 2024 and an anticipated increase to 28.6 USD Billion by 2035. This growth trajectory suggests a compound annual growth rate of 6.63% from 2025 to 2035, reflecting the industry's resilience and adaptability. Factors such as technological advancements, increasing demand across various sectors, and a focus on sustainability are likely to contribute to this positive outlook. The market's expansion is indicative of the ongoing evolution of optical coatings and their critical role in modern applications.

Expansion of Consumer Electronics

The expansion of the consumer electronics sector is a pivotal driver for the Global Optical Coatings Market Industry. With the proliferation of devices such as smartphones, tablets, and smart TVs, the demand for high-quality optical coatings is on the rise. These coatings are essential for enhancing display clarity and durability, thereby improving user experience. As manufacturers strive to differentiate their products in a competitive market, the integration of advanced optical coatings becomes increasingly important. This trend is expected to bolster market growth, as consumer electronics continue to evolve and expand, further solidifying the industry's relevance.

Rising Adoption in Renewable Energy

The Global Optical Coatings Market Industry is experiencing increased adoption of optical coatings in renewable energy applications, particularly in solar energy systems. Coatings that enhance light absorption and minimize reflection are critical for improving the efficiency of solar panels. This trend aligns with global efforts to transition towards sustainable energy sources. As governments and organizations worldwide invest in renewable technologies, the demand for high-performance optical coatings is expected to rise. This shift could significantly impact the market, contributing to a projected compound annual growth rate of 6.63% from 2025 to 2035, indicating a robust growth trajectory.

Growing Demand for Advanced Coatings

The Global Optical Coatings Market Industry is witnessing a surge in demand for advanced coatings due to their applications in various sectors such as electronics, automotive, and healthcare. These coatings enhance the performance of optical devices by improving light transmission and reducing glare. For instance, anti-reflective coatings are increasingly utilized in eyeglasses and camera lenses, which is indicative of a broader trend towards high-performance optical solutions. This growing demand is projected to contribute to the market's expansion, with an estimated value of 14.1 USD Billion in 2024, reflecting the industry's potential for innovation and growth.

Increased Focus on Healthcare Applications

The Global Optical Coatings Market Industry is benefiting from an increased focus on healthcare applications, particularly in medical imaging and diagnostic equipment. Optical coatings play a crucial role in enhancing the performance of devices such as endoscopes and imaging systems by improving light transmission and reducing reflections. As the healthcare sector continues to advance technologically, the demand for high-quality optical coatings is likely to rise. This trend underscores the importance of optical coatings in ensuring accurate diagnostics and effective treatments, thereby driving growth in the market.

Technological Advancements in Coating Processes

Technological advancements in coating processes are significantly influencing the Global Optical Coatings Market Industry. Innovations such as atomic layer deposition and magnetron sputtering are enhancing the efficiency and quality of optical coatings. These technologies allow for precise control over the coating thickness and composition, leading to superior optical properties. As a result, manufacturers can produce coatings that meet stringent performance standards across various applications. The ongoing investment in research and development is likely to propel the market forward, with projections indicating a market value of 28.6 USD Billion by 2035, showcasing the industry's commitment to technological excellence.