Stringent Regulatory Standards

The Non-Destructive Testing in Power Generation Market is heavily influenced by stringent regulatory standards imposed by various authorities. Compliance with safety and environmental regulations is paramount for power generation companies. NDT plays a vital role in ensuring that facilities meet these standards by providing reliable inspection methods that detect flaws and prevent failures. Regulatory bodies often mandate regular inspections, which increases the demand for NDT services. As regulations continue to evolve, the need for comprehensive NDT solutions will likely grow, thereby enhancing the market dynamics of the Non-Destructive Testing in Power Generation Market.

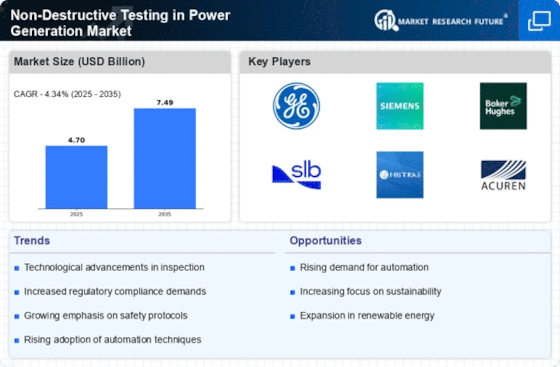

Technological Innovations in NDT

Technological advancements are reshaping the Non-Destructive Testing in Power Generation Market. Innovations such as digital radiography, automated ultrasonic testing, and advanced imaging techniques are enhancing the accuracy and efficiency of inspections. These technologies enable real-time data analysis, allowing for quicker decision-making and improved safety outcomes. The integration of artificial intelligence and machine learning into NDT processes is also emerging, potentially revolutionizing how inspections are conducted. As these technologies become more accessible, they are likely to drive the adoption of NDT solutions in the power generation sector, further propelling the Non-Destructive Testing in Power Generation Market.

Focus on Renewable Energy Sources

The shift towards renewable energy sources is impacting the Non-Destructive Testing in Power Generation Market. As more facilities transition to wind, solar, and hydroelectric power, the need for effective inspection methods remains critical. NDT techniques are essential for ensuring the integrity of new technologies and materials used in renewable energy systems. For instance, the installation of wind turbines requires rigorous testing to prevent failures that could lead to costly downtimes. The increasing investment in renewable energy infrastructure is expected to drive the demand for NDT services, thereby influencing the growth trajectory of the Non-Destructive Testing in Power Generation Market.

Increasing Demand for Energy Efficiency

The Non-Destructive Testing in Power Generation Market is experiencing a surge in demand for energy efficiency. As energy costs continue to rise, power generation facilities are increasingly seeking methods to optimize their operations. Non-destructive testing (NDT) techniques, such as ultrasonic testing and radiographic testing, play a crucial role in identifying inefficiencies and potential failures in equipment. This proactive approach not only enhances operational efficiency but also extends the lifespan of critical assets. According to recent data, the implementation of NDT can lead to a reduction in maintenance costs by up to 30%, thereby driving the growth of the Non-Destructive Testing in Power Generation Market.

Aging Infrastructure and Maintenance Needs

The Non-Destructive Testing in Power Generation Market is significantly influenced by the aging infrastructure of power generation facilities. Many plants are operating beyond their intended lifespan, necessitating regular inspections to ensure safety and reliability. NDT methods are essential for assessing the integrity of aging components, such as boilers and turbines, without causing damage. The need for effective maintenance strategies is underscored by the fact that nearly 40% of power generation assets are over 30 years old. This trend highlights the critical role of NDT in the ongoing maintenance and safety assurance within the Non-Destructive Testing in Power Generation Market.