Safety Enhancements

Safety remains a paramount concern in the Mining Automation Market, with automation technologies playing a crucial role in mitigating risks associated with mining operations. Automated systems can operate in hazardous environments, reducing the need for human presence in dangerous areas. This shift not only protects workers but also enhances overall safety protocols. Data indicates that mines utilizing automation have reported a significant decrease in workplace accidents, with some operations achieving a reduction of over 50% in incidents. As safety regulations become more stringent, the demand for automated solutions that prioritize worker safety is expected to rise. Consequently, mining companies are increasingly investing in automation technologies to comply with safety standards while ensuring the well-being of their workforce.

Cost Reduction Initiatives

The Mining Automation Market is witnessing a growing emphasis on cost reduction initiatives, prompting mining companies to invest in automation technologies. Automation can lead to substantial savings by minimizing labor costs, reducing operational inefficiencies, and optimizing resource utilization. Reports suggest that companies implementing automated solutions can achieve cost reductions of up to 20% in operational expenses. This financial incentive is particularly appealing in a market characterized by fluctuating commodity prices and increasing operational costs. As mining companies strive to maintain profitability, the integration of automation technologies is likely to be viewed as a strategic investment. The potential for long-term savings and improved financial performance is driving the adoption of automation across various mining sectors.

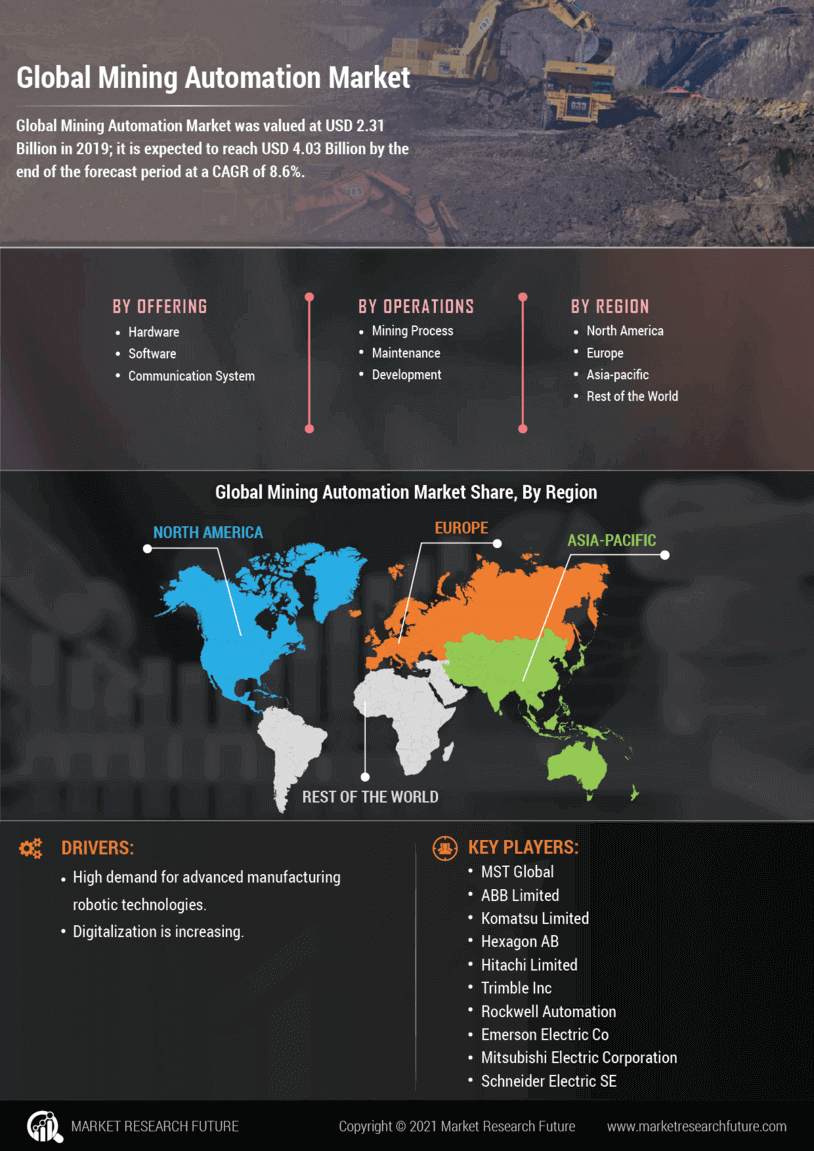

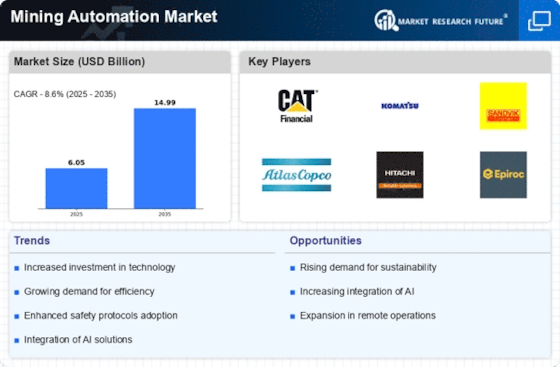

Technological Advancements

Technological advancements are a key driver in the Mining Automation Market, as innovations in robotics, artificial intelligence, and data analytics continue to reshape mining operations. The introduction of sophisticated automation technologies enables mining companies to enhance their operational capabilities and improve decision-making processes. For instance, the use of drones for surveying and monitoring has become increasingly prevalent, providing real-time data that enhances operational efficiency. Furthermore, advancements in machine learning algorithms allow for predictive maintenance, reducing downtime and increasing equipment lifespan. As these technologies evolve, they are expected to play a pivotal role in transforming traditional mining practices, making automation an essential aspect of future mining strategies.

Environmental Sustainability

The Mining Automation Market is increasingly influenced by the growing emphasis on environmental sustainability. Automation technologies are being leveraged to minimize the environmental impact of mining operations. For example, automated systems can optimize energy consumption and reduce waste generation, aligning with global sustainability goals. Data indicates that mining companies adopting automation are likely to achieve a reduction in carbon emissions by up to 30%. This focus on sustainability is not only driven by regulatory pressures but also by consumer demand for environmentally responsible practices. As mining companies seek to enhance their sustainability profiles, the integration of automation technologies is expected to become a fundamental aspect of their operational strategies.

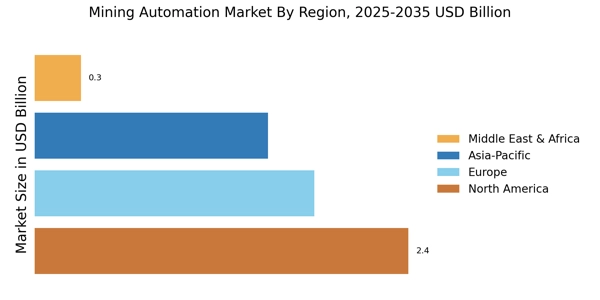

Increased Efficiency and Productivity

The Mining Automation Market is experiencing a surge in demand for automation technologies that enhance operational efficiency and productivity. Automation solutions, such as autonomous vehicles and robotic systems, are being integrated into mining operations to streamline processes. According to recent data, companies that have adopted automation report productivity increases of up to 30%. This trend is driven by the need to optimize resource extraction and reduce operational costs. As mining companies seek to maximize output while minimizing labor costs, the adoption of automated systems is likely to continue growing. Furthermore, the implementation of advanced analytics and machine learning in mining operations is expected to further boost efficiency, making automation a critical component of modern mining strategies.