Rising Demand for Dairy Products

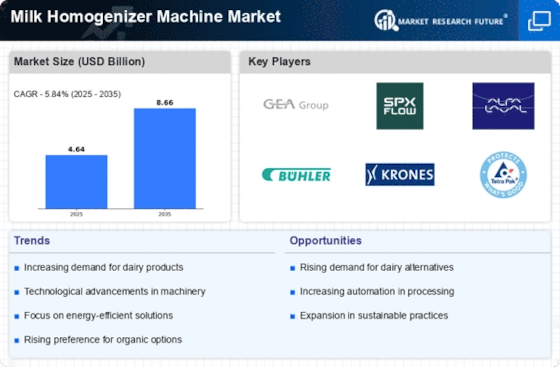

The Milk Homogenizer Machine Market is significantly influenced by the rising demand for dairy products across various regions. As consumer preferences shift towards high-quality dairy items, manufacturers are compelled to invest in advanced homogenization technologies to meet these expectations. Reports indicate that The Milk Homogenizer Machine Market is projected to grow at a compound annual growth rate of 4% over the next five years. This growth is likely to drive the demand for milk homogenizers, as they play a critical role in ensuring product consistency and quality. Consequently, the Milk Homogenizer Machine Market is poised for expansion, driven by the need to cater to an increasingly discerning consumer base.

Focus on Product Quality and Safety

In the Milk Homogenizer Machine Market, there is an increasing emphasis on product quality and safety, which is shaping the landscape of dairy processing. Consumers are becoming more aware of food safety standards, prompting manufacturers to adopt stringent quality control measures. Homogenization is a key process that helps in achieving uniformity and stability in milk products, thereby enhancing safety. Data suggests that approximately 30% of dairy recalls are related to quality issues, underscoring the importance of effective homogenization. As a result, the Milk Homogenizer Machine Market is likely to see a rise in demand for machines that ensure compliance with safety regulations and quality standards.

Expansion of Dairy Processing Facilities

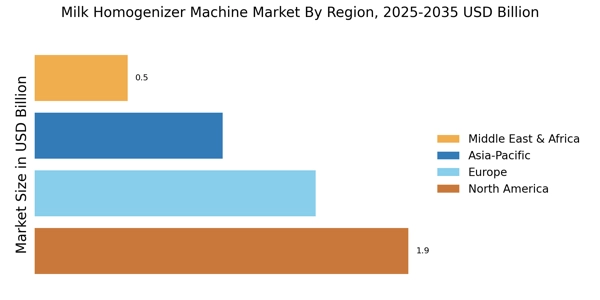

The Milk Homogenizer Machine Market is benefiting from the expansion of dairy processing facilities worldwide. As the demand for dairy products continues to rise, manufacturers are investing in new processing plants and upgrading existing ones to enhance production capacity. This trend is particularly evident in emerging markets, where the dairy sector is experiencing rapid growth. Data shows that the number of dairy processing facilities has increased by 10% in the last two years, indicating a robust investment climate. Consequently, the Milk Homogenizer Machine Market is likely to see increased sales of homogenizers as these facilities seek to optimize their production processes.

Sustainability and Environmental Concerns

The Milk Homogenizer Machine Market is increasingly influenced by sustainability and environmental concerns. As consumers and regulatory bodies advocate for eco-friendly practices, dairy manufacturers are seeking ways to reduce their carbon footprint. Modern homogenization technologies are being developed to minimize energy consumption and waste generation during the milk processing phase. Reports indicate that energy-efficient homogenizers can reduce energy usage by up to 20%, aligning with sustainability goals. This shift towards greener practices is likely to drive innovation within the Milk Homogenizer Machine Market, as companies strive to meet both consumer expectations and regulatory requirements.

Technological Advancements in Milk Homogenizer Machine Market

The Milk Homogenizer Machine Market is experiencing a surge in technological advancements that enhance the efficiency and effectiveness of milk processing. Innovations such as high-pressure homogenization and microfluidization are becoming increasingly prevalent, allowing for finer particle sizes and improved emulsification. These advancements not only improve the quality of milk products but also extend shelf life, which is crucial in a competitive market. According to recent data, the adoption of advanced homogenization techniques has led to a 15% increase in production efficiency for dairy manufacturers. As technology continues to evolve, the Milk Homogenizer Machine Market is likely to witness further enhancements that could redefine processing standards.