Rising Demand in Automotive Sector

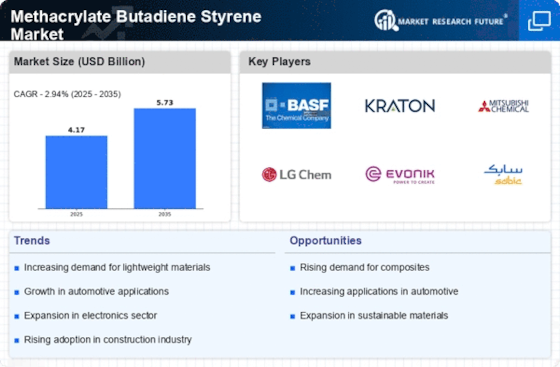

The Methacrylate Butadiene Styrene Market is experiencing a notable surge in demand from the automotive sector. This growth is primarily driven by the increasing need for lightweight materials that enhance fuel efficiency and reduce emissions. Methacrylate Butadiene Styrene Market, known for its excellent impact resistance and thermal stability, is being utilized in various automotive applications, including interior and exterior components. According to recent data, the automotive industry accounts for a substantial share of the overall demand for Methacrylate Butadiene Styrene Market, with projections indicating a compound annual growth rate of approximately 5% over the next few years. This trend suggests that as automotive manufacturers continue to prioritize sustainability and performance, the Methacrylate Butadiene Styrene Market will likely benefit significantly.

Increasing Focus on Sustainable Materials

The Methacrylate Butadiene Styrene Market is being positively influenced by the growing emphasis on sustainability and eco-friendly materials. As industries strive to reduce their carbon footprint, there is a marked shift towards using materials that are recyclable and have a lower environmental impact. Methacrylate Butadiene Styrene Market, with its potential for recycling and reusability, aligns well with these sustainability initiatives. Market analysis suggests that the demand for sustainable materials is expected to grow at a rate of approximately 7% per year, which could significantly enhance the Methacrylate Butadiene Styrene Market. This shift not only reflects changing consumer preferences but also indicates a broader industry trend towards responsible manufacturing practices.

Growth in Electronics and Electrical Applications

The Methacrylate Butadiene Styrene Market is witnessing increased adoption in the electronics and electrical sectors. The material's superior electrical insulation properties and durability make it an ideal choice for various applications, including housings, connectors, and circuit boards. As the demand for consumer electronics continues to rise, manufacturers are increasingly turning to Methacrylate Butadiene Styrene Market for its ability to provide both aesthetic appeal and functional performance. Recent statistics indicate that the electronics sector is projected to contribute significantly to the Methacrylate Butadiene Styrene Market, with an expected growth rate of around 6% annually. This trend underscores the material's versatility and its critical role in meeting the evolving needs of the electronics industry.

Technological Innovations in Manufacturing Processes

The Methacrylate Butadiene Styrene Market is poised for growth due to ongoing technological innovations in manufacturing processes. Advances in production techniques, such as 3D printing and injection molding, are enhancing the efficiency and quality of Methacrylate Butadiene Styrene Market products. These innovations not only reduce production costs but also allow for greater customization and precision in applications. As manufacturers adopt these advanced technologies, the Methacrylate Butadiene Styrene Market is likely to experience a boost in demand, with projections indicating a potential growth rate of 4% annually. This evolution in manufacturing processes reflects a broader trend towards efficiency and innovation in the materials sector.

Expansion of Construction and Infrastructure Projects

The Methacrylate Butadiene Styrene Market is benefiting from the expansion of construction and infrastructure projects worldwide. The material's properties, such as high strength, durability, and resistance to weathering, make it an attractive option for various construction applications, including pipes, fittings, and structural components. With governments and private sectors investing heavily in infrastructure development, the demand for Methacrylate Butadiene Styrene Market is expected to rise. Recent forecasts indicate that the construction sector could see a growth rate of around 5% annually, which would significantly impact the Methacrylate Butadiene Styrene Market. This trend suggests a robust future for the material as it becomes increasingly integral to modern construction practices.