Growing Renewable Energy Sector

The renewable energy sector is expanding rapidly, which presents a significant opportunity for the Metal Fabrication Service Market. As investments in solar, wind, and other renewable technologies increase, the demand for metal components used in energy infrastructure is likely to rise. For instance, solar panel frames and wind turbine structures require precise metal fabrication to ensure durability and efficiency. The global push towards sustainable energy solutions is expected to drive growth in this sector, thereby positively impacting the Metal Fabrication Service Market. This trend indicates a shift towards more environmentally friendly practices, further enhancing the relevance of metal fabrication services.

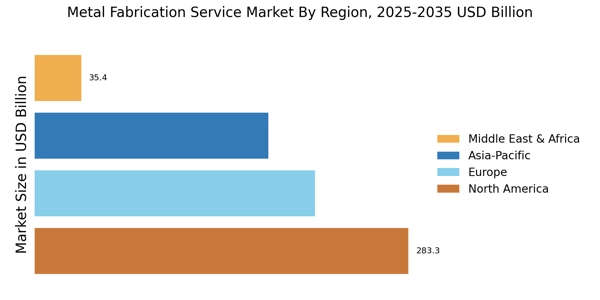

Rising Demand in Construction Sector

The construction sector is experiencing a notable surge, which appears to be a primary driver for the Metal Fabrication Service Market. As urbanization accelerates, the need for robust infrastructure and residential buildings increases. This trend is reflected in the projected growth of the construction industry, which is expected to reach a valuation of over 10 trillion dollars by 2025. Metal fabrication services are essential for producing structural components, reinforcing bars, and other critical elements in construction projects. Consequently, the demand for metal fabrication services is likely to rise in tandem with construction activities, thereby bolstering the Metal Fabrication Service Market.

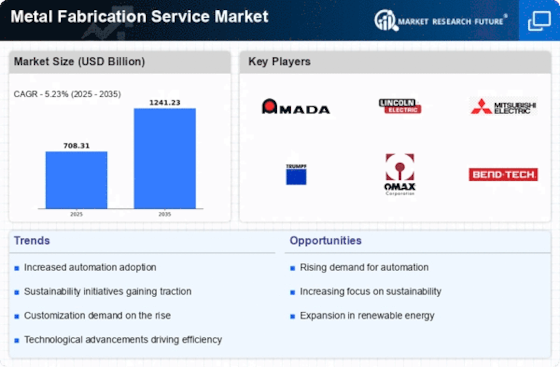

Advancements in Automation and Robotics

Technological innovations, particularly in automation and robotics, are transforming the Metal Fabrication Service Market. The integration of advanced machinery and automated processes enhances efficiency, reduces labor costs, and improves precision in metal fabrication. For instance, the adoption of robotic welding and laser cutting technologies has streamlined production processes, allowing for faster turnaround times and higher quality outputs. As industries increasingly seek to optimize operations, the demand for automated metal fabrication services is expected to grow. This trend not only supports the operational needs of various sectors but also positions the Metal Fabrication Service Market for sustained growth.

Customization and Specialized Solutions

The demand for customized and specialized metal fabrication solutions is on the rise, reflecting a broader trend within the Metal Fabrication Service Market. Industries such as aerospace, automotive, and medical devices increasingly require tailored components that meet specific performance standards. This trend is supported by data indicating that the custom fabrication market is projected to grow significantly, driven by the need for unique designs and specifications. As companies seek to differentiate their products, the ability to provide bespoke metal fabrication services becomes a competitive advantage. This growing inclination towards customization is likely to propel the Metal Fabrication Service Market forward.

Increased Focus on Lightweight Materials

The automotive and aerospace industries are increasingly prioritizing lightweight materials to enhance fuel efficiency and performance. This shift is driving demand for metal fabrication services that specialize in producing lightweight components. The Metal Fabrication Service Market is likely to benefit from this trend, as manufacturers seek to innovate and create parts that meet stringent weight and performance criteria. For example, the use of aluminum and advanced alloys is becoming more prevalent, necessitating specialized fabrication techniques. As these industries evolve, the Metal Fabrication Service Market is positioned to adapt and thrive in response to the growing emphasis on lightweight materials.