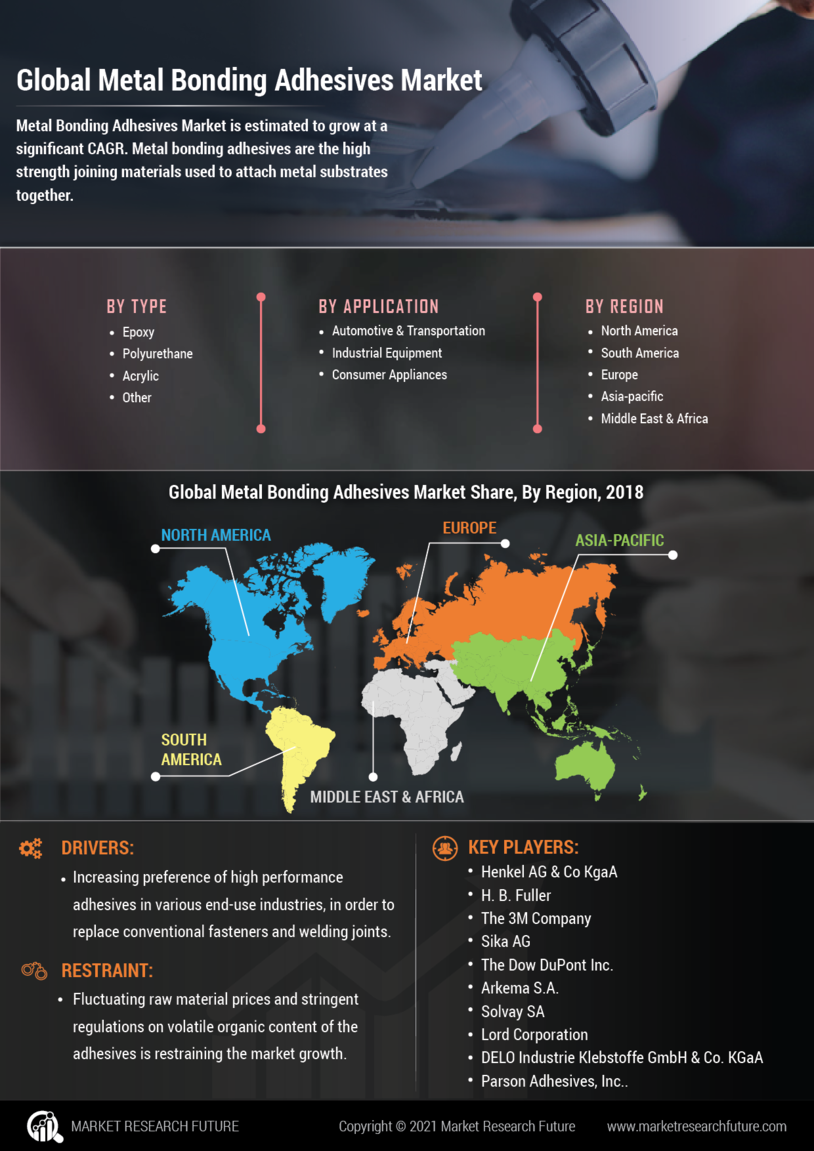

Market Trends and Projections

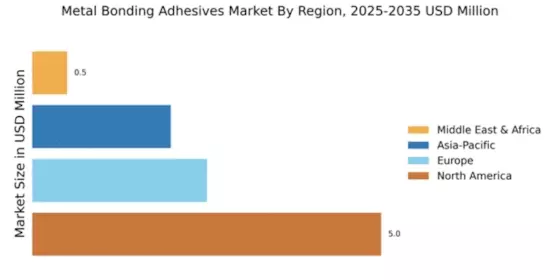

The Global Metal Bonding Adhesives Market Industry is projected to experience substantial growth, with estimates indicating a market size of 8.4 USD Billion in 2024 and a potential increase to 18.9 USD Billion by 2035. This growth reflects a compound annual growth rate of 7.66% from 2025 to 2035, indicating a robust expansion trajectory. The market trends suggest that various sectors, including automotive, aerospace, and construction, will continue to drive demand for advanced bonding solutions. As industries evolve and seek innovative materials, the metal bonding adhesives market is likely to adapt and thrive in response to these changing dynamics.

Growth in Construction Activities

The construction sector is experiencing a resurgence, which is positively impacting the Global Metal Bonding Adhesives Market Industry. As urbanization accelerates globally, the demand for robust and efficient bonding solutions in construction applications is on the rise. Metal bonding adhesives are increasingly utilized in structural applications, facades, and interior fittings, where they provide enhanced strength and durability. This growth is further supported by government initiatives aimed at infrastructure development, which are likely to drive the market forward. The anticipated growth in construction activities suggests a sustained demand for metal bonding adhesives in the coming years.

Expansion of Aerospace Applications

The aerospace industry is increasingly adopting metal bonding adhesives, which is a key driver for the Global Metal Bonding Adhesives Market Industry. These adhesives are essential for assembling lightweight components, which are critical for improving fuel efficiency and performance in aircraft. The growing trend towards composite materials in aerospace applications further necessitates the use of advanced bonding solutions. As the aerospace sector continues to expand, driven by rising air travel demand, the need for high-performance metal bonding adhesives is expected to grow. This trend suggests a promising outlook for the market as aerospace manufacturers seek innovative bonding solutions.

Rising Focus on Sustainable Solutions

Sustainability is becoming a critical focus across various industries, influencing the Global Metal Bonding Adhesives Market Industry. Manufacturers are increasingly seeking eco-friendly adhesive solutions that minimize environmental impact while maintaining performance. This shift is driven by regulatory pressures and consumer preferences for sustainable products. Companies are investing in the development of bio-based adhesives and those with lower volatile organic compounds (VOCs), which are gaining traction in sectors such as automotive and construction. The emphasis on sustainability is likely to shape product offerings and market dynamics, fostering innovation and potentially expanding the market.

Increasing Demand from Automotive Sector

The automotive industry is a primary driver for the Global Metal Bonding Adhesives Market Industry, as manufacturers increasingly seek lightweight materials to enhance fuel efficiency. The shift towards electric vehicles further amplifies this trend, as these vehicles often require advanced bonding solutions for battery components and lightweight structures. In 2024, the market is projected to reach 8.4 USD Billion, with automotive applications accounting for a substantial share. This demand is expected to grow as the industry evolves, potentially leading to a market size of 18.9 USD Billion by 2035, reflecting a compound annual growth rate of 7.66% from 2025 to 2035.

Technological Advancements in Adhesive Formulations

Innovations in adhesive formulations are significantly influencing the Global Metal Bonding Adhesives Market Industry. The development of high-performance adhesives that can withstand extreme temperatures and environmental conditions is becoming increasingly prevalent. For instance, advancements in epoxy and polyurethane adhesives are enabling stronger bonds and improved durability, which are crucial for industries such as aerospace and construction. As these technologies evolve, they are likely to enhance the performance characteristics of metal bonding adhesives, thereby expanding their applications and market reach. This trend indicates a robust growth trajectory for the industry, as manufacturers adopt these advanced solutions.