Membranes Market Summary

As per Market Research Future analysis, the Membranes Market Size was estimated at 8.01 USD Billion in 2024. The Membranes industry is projected to grow from 8.603 USD Billion in 2025 to 17.57 USD Billion by 2035, exhibiting a compound annual growth rate (CAGR) of 7.4% during the forecast period 2025 - 2035

Key Market Trends & Highlights

The Membranes Market is poised for substantial growth driven by technological advancements and increasing demand for sustainable solutions.

- Technological advancements in membrane materials are reshaping the landscape of the Membranes Market.

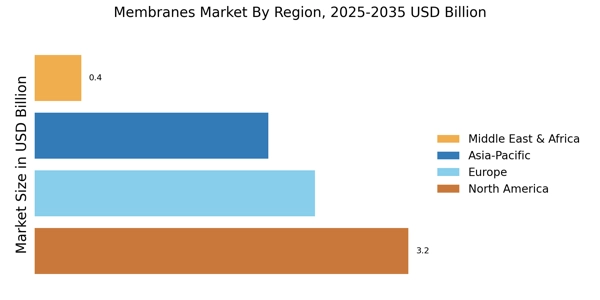

- North America remains the largest market, while Asia-Pacific is emerging as the fastest-growing region.

- Polymeric materials dominate the market, whereas ceramic membranes are witnessing rapid growth.

- Key drivers include increasing water scarcity and regulatory pressures pushing for sustainable water treatment solutions.

Market Size & Forecast

| 2024 Market Size | 8.01 (USD Billion) |

| 2035 Market Size | 17.57 (USD Billion) |

| CAGR (2025 - 2035) | 7.4% |

Major Players

Dow (US), BASF (DE), Suez (FR), Membrane Technology and Research (US), Pall Corporation (US), Toray Industries (JP), Hydranautics (US), Koch Membrane Systems (US), GE Water & Process Technologies (US)