Rising Demand in Electronics

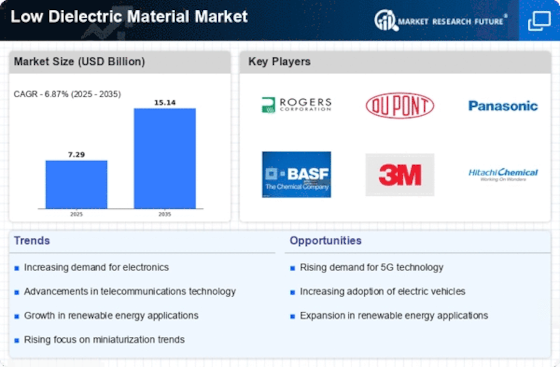

The Low Dielectric Material Market is experiencing a surge in demand driven by the rapid growth of the electronics sector. As devices become increasingly compact and complex, the need for materials that can effectively reduce signal loss and enhance performance is paramount. In 2025, the market for low dielectric materials is projected to reach approximately USD 2 billion, reflecting a compound annual growth rate of around 8%. This growth is largely attributed to the proliferation of smartphones, tablets, and other portable devices that require efficient materials to maintain functionality. Furthermore, advancements in semiconductor technology necessitate the use of low dielectric materials to ensure optimal performance in integrated circuits, thereby propelling the market forward.

Advancements in Material Science

The Low Dielectric Material Market is being propelled by advancements in material science, which are leading to the development of new and improved low dielectric materials. Research and development efforts are focused on creating materials that not only exhibit low dielectric constants but also possess enhanced thermal stability and mechanical properties. These innovations are crucial for meeting the demands of various industries, including telecommunications, automotive, and aerospace. As new materials are introduced to the market, they are expected to drive competition and foster growth within the low dielectric materials sector. By 2025, the impact of these advancements is likely to be reflected in the market dynamics, with an increasing number of applications emerging.

Growth in Automotive Electronics

The Low Dielectric Material Market is benefiting from the expansion of automotive electronics, which is becoming increasingly sophisticated. With the rise of electric vehicles and advanced driver-assistance systems, the demand for low dielectric materials is on the rise. These materials are crucial for ensuring the reliability and efficiency of electronic components in vehicles. In 2025, the automotive sector is projected to contribute significantly to the low dielectric materials market, with an estimated value of USD 500 million. This growth is indicative of the broader trend towards electrification and automation in the automotive industry, where high-performance materials are essential for meeting stringent safety and performance standards.

Emerging Applications in Aerospace

The Low Dielectric Material Market is poised for growth due to emerging applications in the aerospace sector. As the industry seeks to enhance the performance and efficiency of aircraft systems, low dielectric materials are increasingly being utilized in various components. These materials offer advantages such as weight reduction and improved signal integrity, which are critical in aerospace applications. The market is expected to expand as manufacturers adopt these materials to meet regulatory requirements and improve overall aircraft performance. By 2025, the aerospace sector is likely to represent a growing segment of the low dielectric materials market, driven by innovations in design and technology.

Increased Focus on High-Frequency Applications

The Low Dielectric Material Market is significantly influenced by the increasing focus on high-frequency applications. As telecommunications and data transmission technologies evolve, there is a growing need for materials that can operate effectively at higher frequencies. Low dielectric materials are essential in applications such as 5G technology, where signal integrity and minimal loss are critical. The market is expected to witness a notable increase in demand as industries adopt these advanced technologies. In 2025, the market for low dielectric materials in high-frequency applications is anticipated to account for a substantial share, driven by the need for reliable and efficient communication systems.