Technological Innovations

Technological advancements are playing a pivotal role in shaping the Liquid Ring Compressor Market. Innovations in design and materials are enhancing the performance and reliability of these compressors. For instance, the integration of advanced monitoring systems allows for real-time performance tracking, which can lead to improved maintenance and reduced downtime. Furthermore, the development of more durable materials is extending the lifespan of liquid ring compressors, making them a more attractive investment for industries. As technology continues to evolve, the market is expected to see a rise in demand for next-generation liquid ring compressors that offer enhanced efficiency and lower operational costs, thereby solidifying their position in various applications.

Focus on Energy Efficiency

Energy efficiency remains a critical focus within the Liquid Ring Compressor Market, as industries strive to reduce operational costs and environmental impact. Liquid ring compressors are recognized for their energy-efficient performance, which is essential in an era where energy consumption is under scrutiny. The ability of these compressors to operate effectively with minimal energy input makes them an attractive option for companies aiming to enhance sustainability. Recent studies indicate that energy-efficient compressors can reduce energy costs by up to 20% compared to traditional systems. This emphasis on energy efficiency is likely to drive further adoption of liquid ring compressors across various sectors, reinforcing their role in promoting sustainable industrial practices.

Rising Industrial Applications

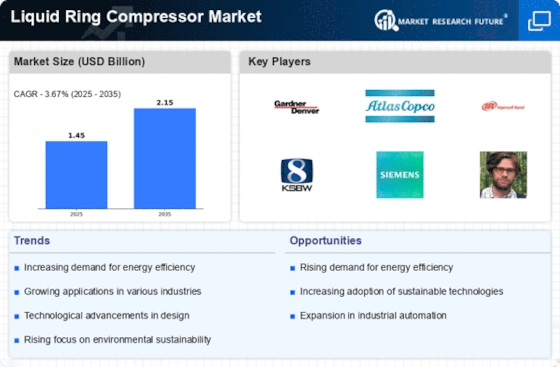

The Liquid Ring Compressor Market is witnessing an increase in applications across various industrial sectors, including chemical processing, pharmaceuticals, and food and beverage. These compressors are particularly valued for their ability to handle corrosive and volatile gases, making them suitable for diverse industrial environments. The chemical processing industry, for instance, is projected to contribute significantly to market growth, with a compound annual growth rate of approximately 5% over the next few years. This expansion is likely to be fueled by the ongoing need for efficient gas handling solutions in manufacturing processes. As industries continue to evolve, the versatility of liquid ring compressors positions them as a preferred choice for many applications, thereby enhancing their market presence.

Increasing Demand in Oil and Gas Sector

The Liquid Ring Compressor Market is experiencing a notable surge in demand, particularly within the oil and gas sector. This growth is primarily driven by the need for efficient gas extraction and processing technologies. Liquid ring compressors are favored for their ability to handle wet gases and maintain high efficiency under varying conditions. As the oil and gas industry continues to expand, the demand for reliable and efficient compression solutions is expected to rise. Recent estimates suggest that the oil and gas sector accounts for a significant portion of the liquid ring compressor market, potentially exceeding 30% of total market share. This trend indicates a robust future for liquid ring compressors as they become integral to modern extraction and processing operations.

Regulatory Compliance and Safety Standards

The Liquid Ring Compressor Market is increasingly influenced by stringent regulatory compliance and safety standards across various sectors. Industries are required to adhere to environmental regulations that mandate the use of equipment that minimizes emissions and enhances safety. Liquid ring compressors, known for their low emissions and safe operation, are well-positioned to meet these regulatory demands. As companies strive to comply with these regulations, the demand for liquid ring compressors is likely to increase. This trend is particularly evident in sectors such as waste management and chemical processing, where safety and environmental considerations are paramount. The alignment of liquid ring compressors with regulatory requirements may drive their adoption, further expanding their market share.